Interesting article and I very much like the possibilities..I will be watching.

Enovix Ships Commercial Batteries from Fab-1 Production Line

Jun 21, 2022

Download PDF

Enovix Ships Commercial Batteries from Fab-1 Production Line

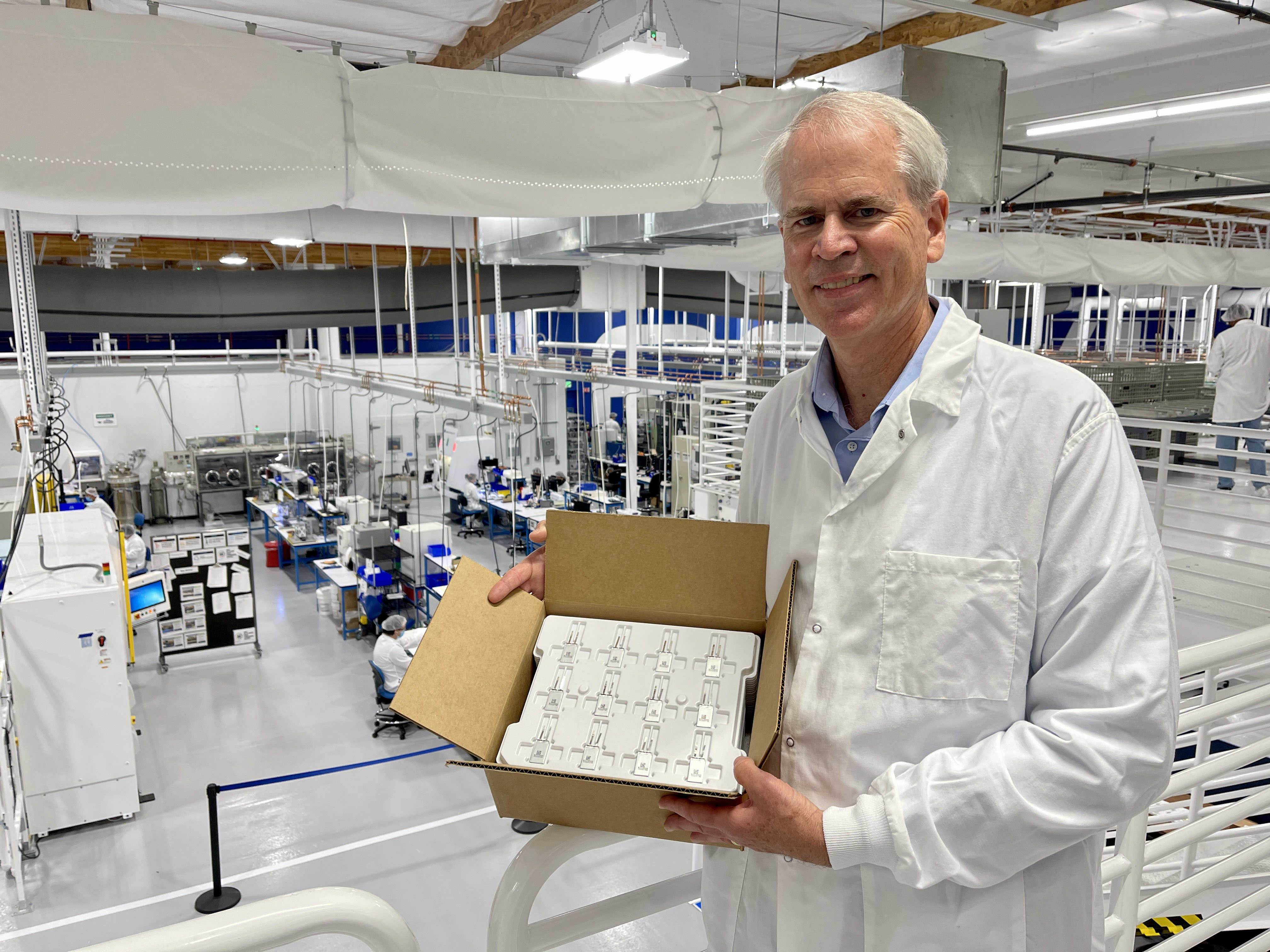

Enovix Co-Founder, President and CEO Harrold Rust

FREMONT, Calif., June 21, 2022 (GLOBE NEWSWIRE) -- Enovix Corporation (“Enovix”) (Nasdaq: ENVX), the leader in the design and manufacture of next generation 3D Silicon™ Lithium-ion batteries, today announced it has shipped its first commercial cells for revenue.

“Due to the resilience, innovation and customer focus of the entire team at Enovix, we’re pleased to announce we have shipped our first commercial battery cells out of our factory in Fremont, Calif.,” said Harrold Rust, Co-founder, President and Chief Executive Officer of Enovix. “This milestone marks the culmination of more than 14 years of hard work developing and qualifying our revolutionary technology and a first-of-its-kind, fully automated production line. We’re focused now on meeting the high demand for our battery by continuing to scale production at our Fab-1 site, while at the same time, executing on the design and procurement of our Gen-2 production lines. I couldn’t be prouder of the team.”

Shipping commercial cells is the next milestone in the company’s growth. Earlier this year, Enovix announced it delivered qualification cells to customers.

“With the start of commercial production, Enovix customers now have the opportunity to realize a meaningful advantage over their competition, while companies that take a wait-and-see approach, sticking with legacy battery designs, risk being left behind,” said Cam Dales, General Manager and Chief Commercial Officer at Enovix. “Over the coming months and years, we look forward to accelerating our output to serve customers with advanced batteries that can uniquely enable their next-generation devices.”