I assume that a voltage follower could track a discharging capacitor without dropping any further voltage, and thus without needing to dissipate any heat. The PWM would require an oscillator and pulse width generating circuits, so perhaps not quite as simple. To be honest, I haven't actually tried designing both circuits to see which would indeed have the lowest parts count and highest efficiency, although the lamp wastes 5W and that leaves a lot of room for inefficient circuits.I doubt they would adjust the voltage, because that presents a heat dissipation problem with the driver transistor. More likely they pulse-width-modulate (PWM) the 12VDC. That's much more efficient, simpler, and cheaper.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing incandescent bulbs with cool LED alternatives?

- Thread starter S-2000 Roadster

- Start date

-

- Tags

- Roadster

I assume that a voltage follower could track a discharging capacitor without dropping any further voltage, and thus without needing to dissipate any heat. The PWM would require an oscillator and pulse width generating circuits, so perhaps not quite as simple. To be honest, I haven't actually tried designing both circuits to see which would indeed have the lowest parts count and highest efficiency, although the lamp wastes 5W and that leaves a lot of room for inefficient circuits.

Complexity is irrelevant with modern electronics manufacturing. Cost, reliability, and size matters. Especially cost.

Ignoring the switching transistor, which you need in either case, let's compare cost and size:

You'd need a pretty big capacitor to hold up an incandescent light bulb for any substantial amount of time. It would be physically quite large, and cost at least several bucks. Electrolytic capacitors can have long-term reliability issues.

Using the tiniest, dumbest, and cheapest PIC microcontroller to run the switch, the cost is $0.35 in quantity and the thing is smaller than the switching transistor. And you probably don't even need a dedicated controller; probably auxiliary functions like this are run by a shared controller.

Complexity is related to cost, both in parts count and in the price of specific parts. As important as cost is, complexity cannot be entirely irrelevant. Don't forget the cost of developing the PIC firmware, not to mention the cost of either ordering the PIC with a custom mask ROM or the time needed to load the firmware into Flash. Analog electronics are 'programmed' to operate correctly as soon as they are soldered together.Complexity is irrelevant with modern electronics manufacturing. Cost, reliability, and size matters. Especially cost.

Ignoring the switching transistor, which you need in either case, let's compare cost and size:

You'd need a pretty big capacitor to hold up an incandescent light bulb for any substantial amount of time. It would be physically quite large, and cost at least several bucks. Electrolytic capacitors can have long-term reliability issues.

Using the tiniest, dumbest, and cheapest PIC microcontroller to run the switch, the cost is $0.35 in quantity and the thing is smaller than the switching transistor. And you probably don't even need a dedicated controller; probably auxiliary functions like this are run by a shared controller.

With a voltage follower, the capacitor does not supply any current to the load, so the capacitor can be any size to make the RC product deliver the desired time constant. The power transistor merely duplicates the voltage using the 12 V battery source and perhaps some cascoding. So, perhaps a single transistor would be an inefficient design, but efficiency is rather moot when the bulk of the 5 W incandescent power goes into heat loss. You can afford to shift some or all of that same 5W loss into the power transistor when dimming without suffering a net loss in efficiency.

But you may be right. Every day I learn a new function of the Roadster which exhibits some degree of latency that far exceeds pure analog electronic technology, leading me to believe that too many functions are running through an underpowered controller. I've lost track of the number of buttons and switches on the Roadster that take a perceivable fraction of a second to respond. I really hope the Model S performs much quicker on all of these functions.

Last edited:

But you may be right. Every day I learn a new function of the Roadster which exhibits some degree of latency that far exceeds pure analog electronic technology, leading me to believe that too many functions are running through an underpowered controller. I've lost track of the number of buttons and switches on the Roadster that take a perceivable fraction of a second to respond. I really hope the Model S performs much quicker on all of these functions.

I'm not forgetting development cost, but speaking as a designer of aggressively-priced electronics, personally I'd use the PIC. (That's from someone who considers programming PICs to be highly annoying.)

Yes, there seems to be a cycle time of 1 second for just about every input on the car (but not the accelerator!). I suspect that's a function of some kind of bus polling. I doubt it's due to an underpowered processor; it could well be a less-than-ideal architecture decision made early in the project.

I use the PIC family, where appropriate, and find programming it in C to be quite easy. I still write the interrupt routines in assembly to avoid the massive function entry and exit code that is produced by the C compiler, and sometimes other pieces end up in assembly. But I do have one pure assembly side project that has never gotten off the ground - I don't know if the lack of a C compiler or lack of a budget is the biggest culprit.I'm not forgetting development cost, but speaking as a designer of aggressively-priced electronics, personally I'd use the PIC. (That's from someone who considers programming PICs to be highly annoying.)

They say that cars have hundreds of microprocessors these days, but I don't know how accurate that number or designation might be (perhaps they're counting all chips with serial digital interfaces as a 'processor'). If there are more than two processors in the car, then I'm sure it's possible that one or more is underpowered. The DSP in the PEM is certainly not underpowered, but it does not run everything. There is a Linux computer in there, and I wonder if it has a bad I/O latency for peripherals or just bad programming ... maybe there's limited I/O.Yes, there seems to be a cycle time of 1 second for just about every input on the car (but not the accelerator!). I suspect that's a function of some kind of bus polling. I doubt it's due to an underpowered processor; it could well be a less-than-ideal architecture decision made early in the project.

strider

Active Member

S2K - thanks for the recos. However, how do you get the dome light cover off to replace the bulb? I was able to do the trunk and license plate bulbs w/ ease but I'm worried I'm going to break some tiny piece of plastic that will cost me $200 for a replacement.

That's a good question, and I struggled with this for a while, so don't feel like you're alone in worrying about how to do it.S2K - thanks for the recos. However, how do you get the dome light cover off to replace the bulb? I was able to do the trunk and license plate bulbs w/ ease but I'm worried I'm going to break some tiny piece of plastic that will cost me $200 for a replacement.

Basically, there is a clear plastic lens inside a dark plastic frame. The clear plastic is able to rotate within the dark plastic from to turn the dome light On/Door/Off. The dark plastic frame simply snaps into the body panel below the roll bar, in front of the rear window. To remove the dome light, just pull one side of this frame out until the whole thing comes loose. It helps to have the dome light on when you do this, because the light spilling around inside the panel will show you how the dome light snaps in.

DO NOT TRY TO REMOVE THE CLEAR PLASTIC PIECE FROM THE DARKER PLASTIC FRAME!

(I did that, and it took an incredible amount of manual dexterity to get the thing back together. The only reason I even attempted that level of disassembly was to see if I could fit a larger, brighter LED structure inside - no luck, and thus it's not worth taking apart)

To put it another way, when you say "dome light cover" - I get the impression that you're headed in the wrong direction. You can't really remove the cover. You actually remove the entire dome light assembly, then remove the bulb from the back side. At no time is there ever a "cover" that can be removed. Hopefully this makes things more understandable.

After you remove the whole dome light assembly from the panel, it's fairly obvious how to rotate the bulb and remove the socket. You'll insert the LED replacement into the socket, then twist and lock the pair into the dome assembly. Finally, snap the whole thing back into the panel.

The car will time out if you take a long time doing this, so the LED might not work when you first plug it in. If that's the case, close your door and open it again, or basically do anything that would normally cause the interior dome light to turn on. You can even briefly restore the incandescent bulb to confirm that the dome light assembly is getting power. This will help you make sure that you have the LED installed correctly, because many versions will not light up if the '+' and '-' sides are reversed. If the LED doesn't work but the incandescent does, then simply try rotating the LED 180 degrees and try again. I can't remember which LED models were polarized and which were universal. I noticed that the more expensive ones seem to be wired to work either way, but the cheaper LEDs will only work with the proper polarity.

Note: The incandescent bulb will be hot if you've left it on while disassembling everything. Don't burn yourself. Also, it might be worth simply taking the LED into your Tesla Store or service and have them do this for you. I don't want to be responsible for anyone damaging their fine Roadster if my instructions are not clear.

strider

Active Member

Of course - I am responsible for my own screwdriver gougesNote: The incandescent bulb will be hot if you've left it on while disassembling everything. Don't burn yourself. Also, it might be worth simply taking the LED into your Tesla Store or service and have them do this for you. I don't want to be responsible for anyone damaging their fine Roadster if my instructions are not clear.

dhrivnak

Active Member

I ordered the 6 light replacement (3710-xHP6) from Super Bright LEDs for the trunk light and the 3 light (3710-xHP3) for the license light and both were EASILY replaced and are much cooler. Thank you for the suggestion and the tips on installation.

This forum is a wealth of knowledge. Thank you all

This forum is a wealth of knowledge. Thank you all

I ordered the 6 light replacement (3710-xHP6) from Super Bright LEDs for the trunk light and the 3 light (3710-xHP3) for the license light and both were EASILY replaced and are much cooler. Thank you for the suggestion and the tips on installation.

This forum is a wealth of knowledge. Thank you all

Cool. Every time I see my Roadster lit up at night, it will be nice to think of the fact that it's not the only "upgraded" Roadster on the road.

NigelM

Recovering Member

sprediletto

Member

License Plate Light Comparison

On the left, a 3710-xHP3 LED from superbrightleds.com

On the right, stock incandescent light

On the left, a 3710-xHP3 LED from superbrightleds.com

On the right, stock incandescent light

Last edited:

sprediletto

Member

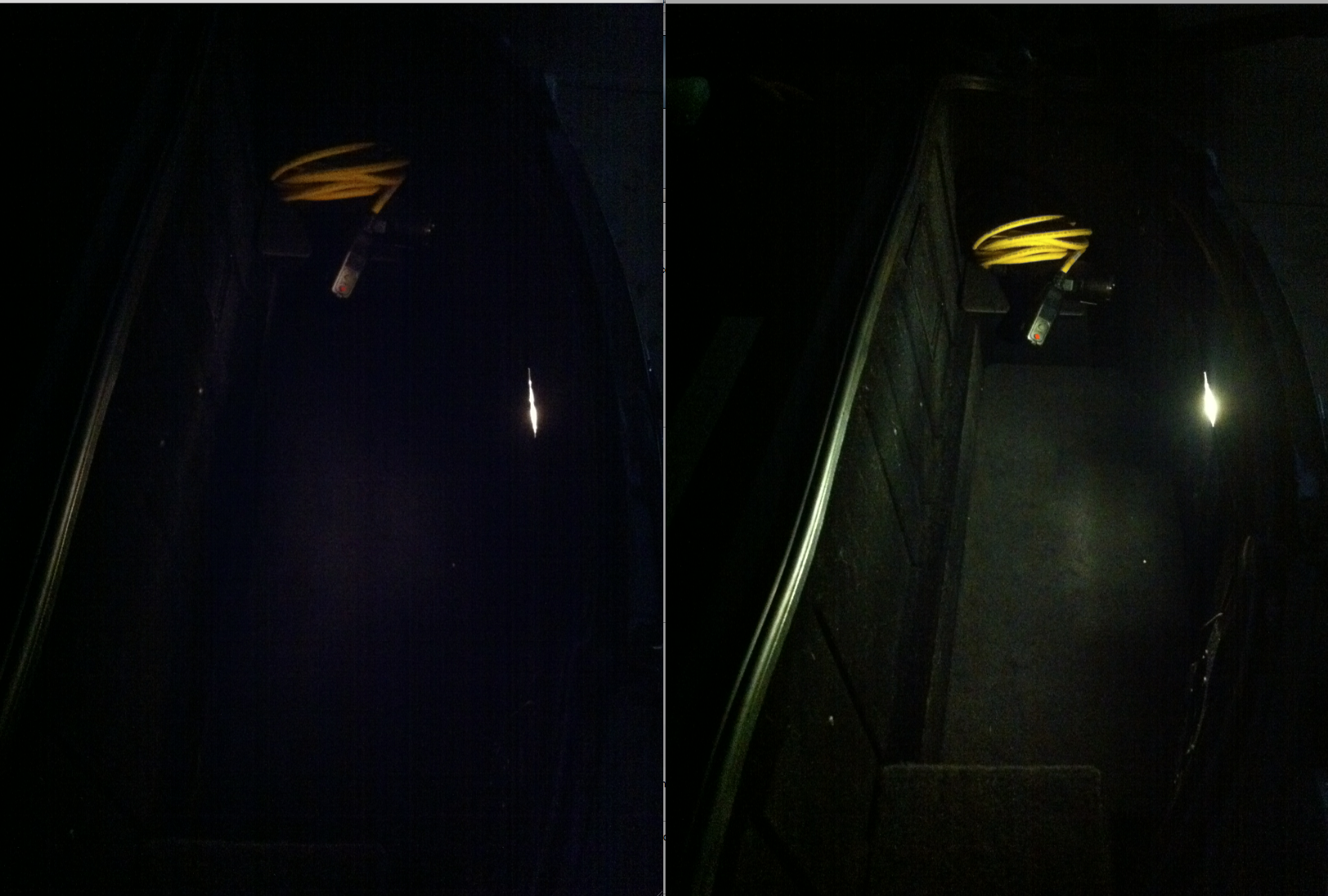

Trunk Light Comparison

On the left, stock bulb

On the right, a 3710-xHP6 LED from superbrightleds.com

On the left, stock bulb

On the right, a 3710-xHP6 LED from superbrightleds.com

Last edited:

sprediletto

Member

Interior Dome Light Comparison

On the left, stock bulb

On the right, a WLED-xHP LED from superbrightleds.com

On the left, stock bulb

On the right, a WLED-xHP LED from superbrightleds.com

Jaff

Active Member

Thanks for the comparative pics Spred...very interesting to see the difference!...BTW, have you got a bulb that makes the license plates look dimmer...no need to help out the photo-radar folks! :wink::biggrin:

NigelM

Recovering Member

Fitted the bulbs, they look great. Here's 2 tips:

1) The dome interior dome light is a rocker and the "permanently on" setting left the light pointing backwards. There's plenty of spare cable in there so I just rotated the whole thing 180° and now it points forwards into the cabin when I turn it on. (Hope that makes sense!)

2) Remember to order 2 bulbs for the license plate lights. redface

redface

1) The dome interior dome light is a rocker and the "permanently on" setting left the light pointing backwards. There's plenty of spare cable in there so I just rotated the whole thing 180° and now it points forwards into the cabin when I turn it on. (Hope that makes sense!)

2) Remember to order 2 bulbs for the license plate lights.

I have the same 3610-NW4 LED model on both the left and the right, yet I still have a similar difference in brightness on my license plate. That's because rotating the right LED to avoid glare in the cheap, plastic backup camera lens ends up reducing the brightness quite a bit. I guess I could rotate the other side to match and still have enough brightness to meet regulations, but I figure it doesn't hurt to leave it unbalanced.On the left, a 3710-xHP3 LED from superbrightleds.com

On the right, stock incandescent light

By the way, I don't see that I documented this anywhere else on the 4 pages of this thread, but it looks like I decided against using the 3710-CWHP3 LEDs that I have because they are so ridiculously bright. The 3610-NW4 is tame in comparison, yet still brighter than the incandescents.

Yes, that makes sense, and it's a great suggestion. I'll take a look tomorrow. I rarely turn the dome light on, manually, but it might as well be facing in the more optimal direction (maybe mine already is).The dome interior dome light is a rocker and the "permanently on" setting left the light pointing backwards. There's plenty of spare cable in there so I just rotated the whole thing 180° and now it points forwards into the cabin when I turn it on. (Hope that makes sense!)

NigelM

Recovering Member

I pointed my 3710-CWHP3 LEDs straight down and then about 15° backwards towards the plate. I have almost zero flare on the camera but I get a really cool kind of ghostly white down on the road under the diffuser. I'm told it's not disturbing to other drivers, at least no more than the bright rear lights in any case.

Quick followup: I've had one or two 3610-NW4 LEDs go bad on me. They start flickering even when the car's not moving. I just replaced the second one now (but I used a 3610-CW4 that is probably going to end up the same).

I really wish these worked because they're cheaper and not so bright. If you're really worried, try the 3610-NW4 or maybe the 3610-WW4. Between the 3710-xHP3 and 3710-xHP6, you definitely want the x3 because the x6 is way brighter.BTW, have you got a bulb that makes the license plates look dimmer...no need to help out the photo-radar folks! :wink::biggrin:

Similar threads

- Replies

- 13

- Views

- 770

- Replies

- 203

- Views

- 8K

- Replies

- 56

- Views

- 8K

- Replies

- 26

- Views

- 7K