stopcrazypp

Well-Known Member

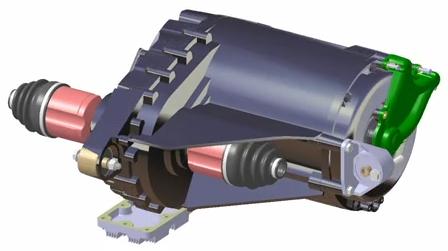

I think the Model S motor is in 1:17-1:22 of this investor's video.

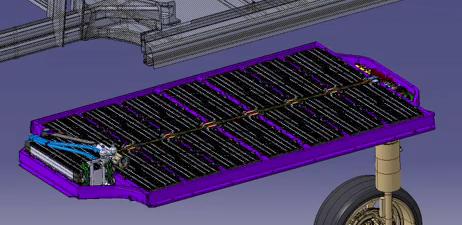

0:26-0:28 shows how the batteries are laid out.

0:26-0:28 shows how the batteries are laid out.

Last edited by a moderator:

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

If a model s rotor is 12.8 inches, how small is the roadster rotor?Do we have a size reference? This picture

is of a Model S rotor at 12.8 inches.

Stop's post of the motor assembly cad is nothing like these pictures and the videos show a much smaller Roadster rotor.But who says the demo cars do not use available bits to get it going for now. If only Tela employees can drive it there may be no 0-60 testing by potential "customers".

If a model s rotor is 12.8 inches, how small is the roadster rotor?

I think the above is exterior dimension. My guess would be 9" rotor diameter...."the size of our motor it's about 10 or 12 inches in diameter and 12 to 14 inches in length and that's it"...

Multiple points:

Output from a cell is expressed in its C rating. When you pull 1C from a 2200mAh cell you get 2.2amps, when you pull 5C you get 11amps.

It is most likely that you can pull 5C from a 2600 the same as you can from a 2200, meaning the 2600 can put out 13amps, which also means that power density increases at the same rate as energy density.

I found some LG-Chem cells on a website that have a 2200 mAh 18650 at 45g a 2400 mAh at 46.5g and an 2600 mAh at 48g

( A 6% increase in mass for an 18% increase in energy and power )

So 6831 of the Roadster cells is about 674 pounds.

Clearly the energy density improves in both volume and mass with the better cells.

The 42kW pack at 5C has 210kW available, but the 60kW pack at 5C has 300kW available.

The 42kW pack should be a lot lighter, it will be interesting to compare the acceleration between them.

Also I did some other poking around on some laptop websites and a lot of the 6 cell laptop batteries I found are most likely 2200mAh cells, but the 9 cell batteries I found were most likely 2600mAh cells.

...

Tesla’s battery packs may cost as little as $200 per kilowatt hour, compared with about $700 to $800 per kilowatt hour for so-called large-form cell lithium-ion packs, Martin Eberhard, a Tesla founder and former chief executive, said in an interview last month. Straubel declined to confirm Eberhard’s estimate or discuss the cost of Tesla’s battery packs...

Nissan’s choice of a larger type of lithium-ion battery means “they will have a cost challenge that will be more difficult to solve,” Straubel said yesterday in an interview. “It will require a lot higher volume before they really get to a cost point that is internally sustainable.”...

This most obvious influence of this safety drumbeat is how the Model S's battery lays like a slab at the bottom of the chassis, benefitting packaging, underbody aerodynamics, and center of gravity issues. Appearing to be about the size of a 4 x 8 sheet of plywood and roughly 4 1/2 inches thick (with the corners scalloped off), the battery's structural encasement, all by itself, offers more torsional rigidity than the Roadster's entire chassis. Internal structures should make it robust enough to satisfy the government's upcoming side pole impact standards, yet it might be removable in about a minute. When asked if this suggests a collaboration with Better Life (proponents of fast-swappable batteries) the answer was no -- but you have to wonder what the purpose of it is, then. The battery enclosure will also be employed as a stiff basis for the Model S's steering rack.

And, in the works is an SAE 1772 adaptor for the Roadster's now non-SAE-standard charging coupling.

Rawlinson's presentation provided additional glimpses into the Model S's development, including its double A-arm front suspension, multi-link rear suspension that'll be packaged with its liquid-cooled motor, and its comprehensive aluminum structure (a specialty of his).

... yet it might be removable in about a minute. ....-- but you have to wonder what the purpose of it is, then.

ummm... I believe you're looking at empty shelves, conveniently labeled with part numbers of what should go there. Looks like the shelves have rollers so it's easier to slide bins off and on them. Do you have a source for the image?

Just curious. Who makes the electric motor itself? Does Tesla do that in house or is it a part that they buy from another manufacturer?