Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Free Destination Charging: 50x L2 80A Stations @ Caltech, Pasadena, CA

- Thread starter MITE46

- Start date

Cottonwood

Roadster#433, Model S#S37

probably my firewall...let me take a look

All working now! Thanks!!

Congrats on making a huge project come to life!

I look forward to hearing how dynamic current adjustment on the J1772 EVSE's works.

rolls and rolls of cable...

20,000+ ft of copper...average run 130ft, 2 conductors + shared grounds, 54x runs...

Starting at the far side of every gutter...

Run the wire all the way back to the breakers...

While that is happening, I've been assembling the stations...a lot more work that I had imagined.

20,000+ ft of copper...average run 130ft, 2 conductors + shared grounds, 54x runs...

Starting at the far side of every gutter...

Run the wire all the way back to the breakers...

While that is happening, I've been assembling the stations...a lot more work that I had imagined.

FlatSix911

Porsche 918 Hybrid

Not a car in the lot...good time to get to work!

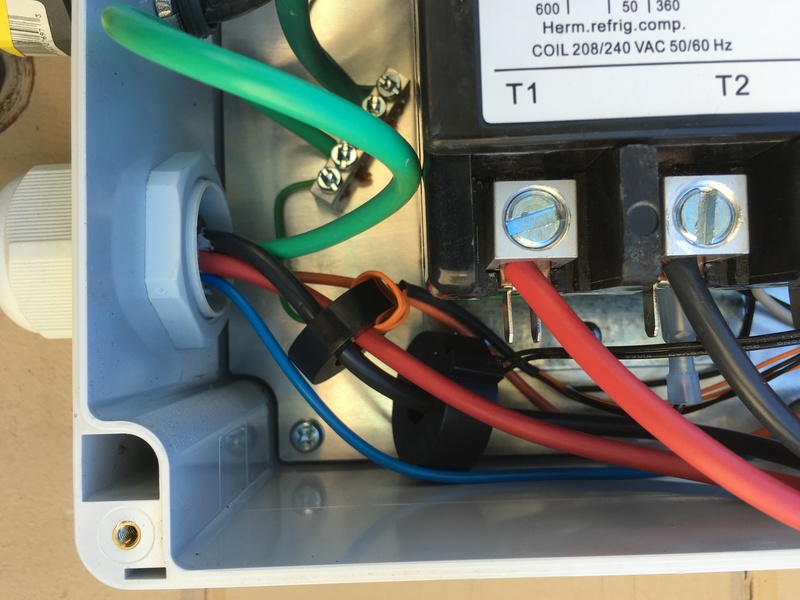

Started to install the guts of the stations...

We're using 25ft cords, but then after trying it out with a retractable cord management system, we decided to chop the cable down to 18ft and force Tesla's and i3's to back in. I've got a bunch of 7ft 80A cords if anyone wants some short ones!

The first couple were fun...the next 25 became tedious...We need to find a place to mass manufacturer these things =)

Aye, L2 stations as far as the eye can see....ready for juice!

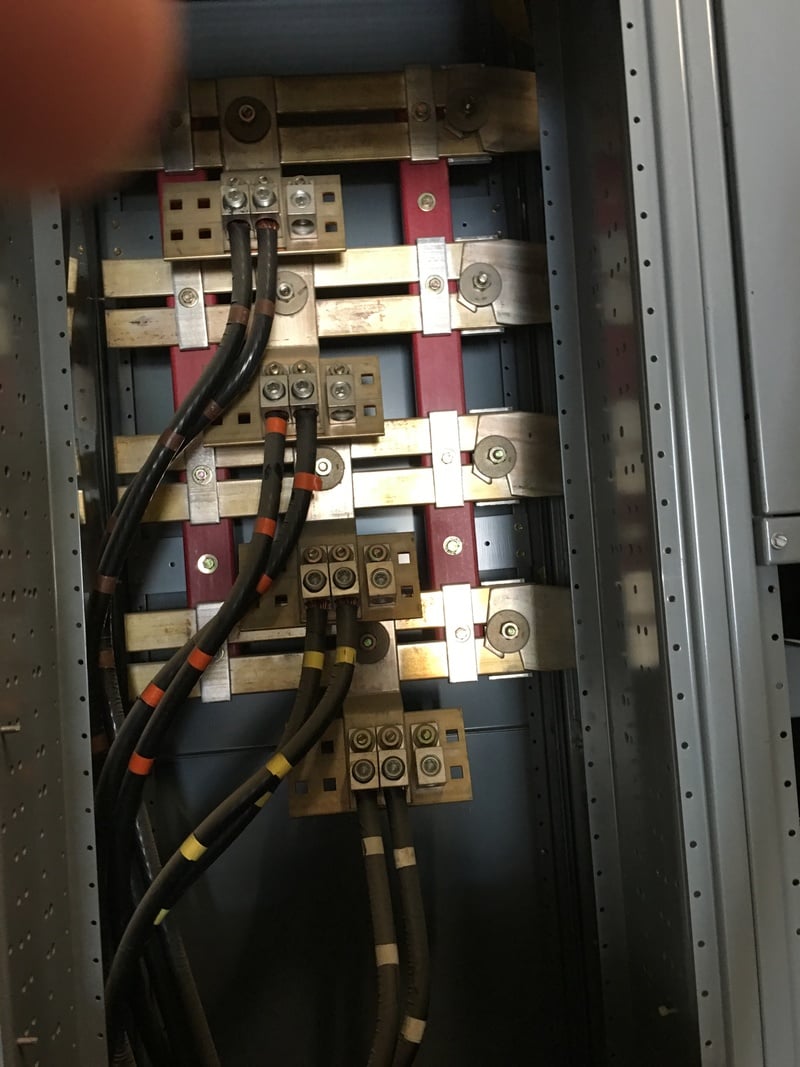

Juice day...had to shut down the power to the whole building because our wires are really close to the bus bars...don't want to touch that and die.

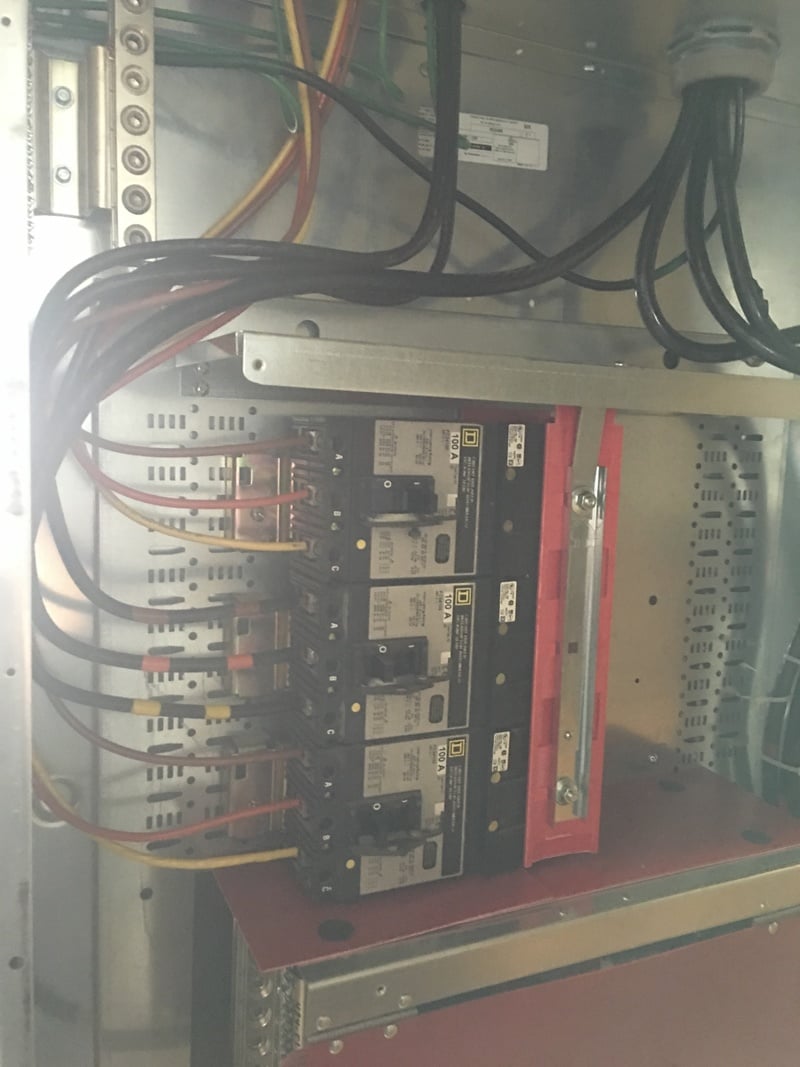

The switchboard was completely full, so we had to relocate some breakers to a new sub panel to make space.

New 225A 480v breakers going in...one for each transformer, and one for the new subpanel.

While we have access to the panel, might as well install CTs for monitoring...

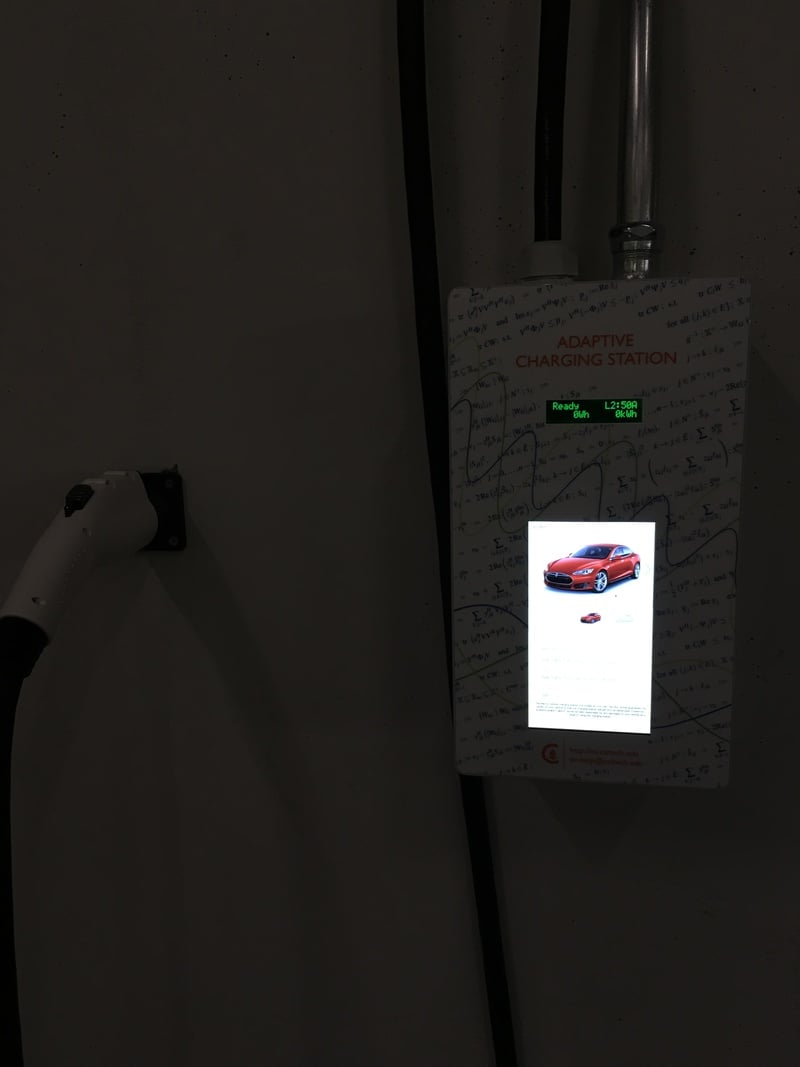

We got power! So far so good...This will end range anxiety for some people =)

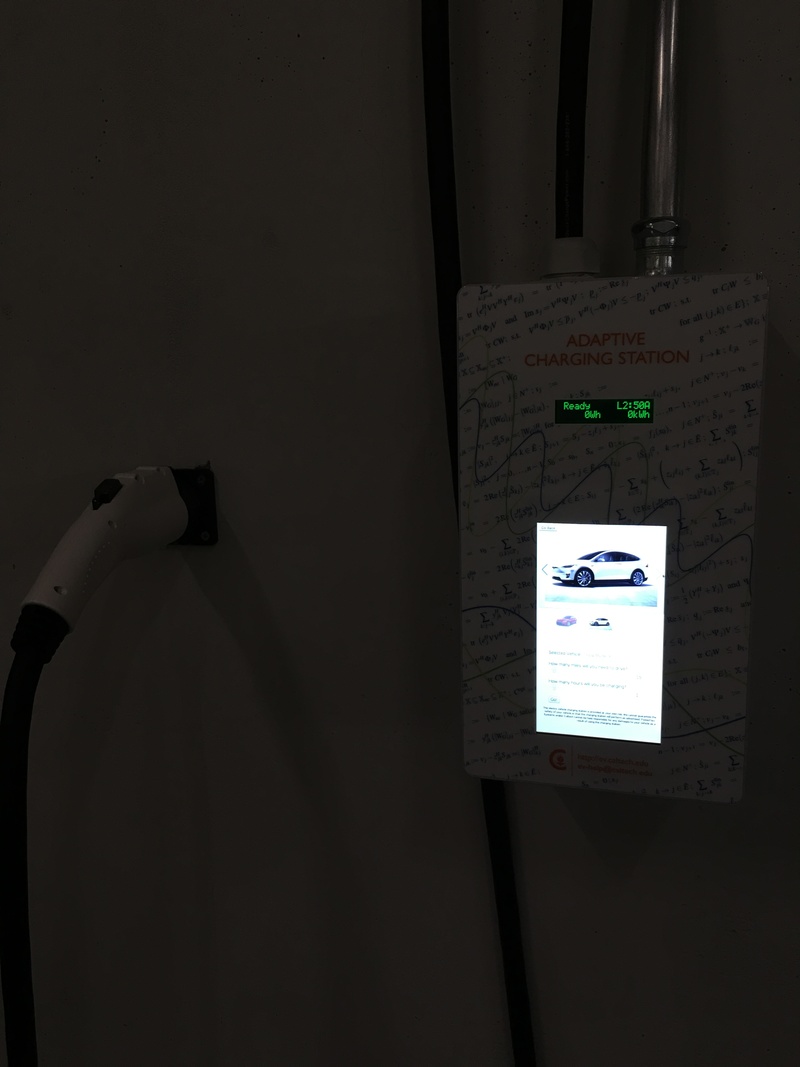

Sneak peek at our Adaptive Charging Station...you can pick your EV on the touch screen or the mobile app...In this case we can pick model S...which loads a profile for wh/mile. We are keeping it at 50A for the first few weeks...then move up to 80A via software.

Here's model X...We are collecting things like how long do you plan to stay parked, how many miles do you need at a minimum...

We've got the first row of 30x stations done, since that is all that will fit in a model s...next time we will finish the remaining 24x...More details on scheduling algorithms soon!

Started to install the guts of the stations...

We're using 25ft cords, but then after trying it out with a retractable cord management system, we decided to chop the cable down to 18ft and force Tesla's and i3's to back in. I've got a bunch of 7ft 80A cords if anyone wants some short ones!

The first couple were fun...the next 25 became tedious...We need to find a place to mass manufacturer these things =)

Aye, L2 stations as far as the eye can see....ready for juice!

Juice day...had to shut down the power to the whole building because our wires are really close to the bus bars...don't want to touch that and die.

The switchboard was completely full, so we had to relocate some breakers to a new sub panel to make space.

New 225A 480v breakers going in...one for each transformer, and one for the new subpanel.

While we have access to the panel, might as well install CTs for monitoring...

We got power! So far so good...This will end range anxiety for some people =)

Sneak peek at our Adaptive Charging Station...you can pick your EV on the touch screen or the mobile app...In this case we can pick model S...which loads a profile for wh/mile. We are keeping it at 50A for the first few weeks...then move up to 80A via software.

Here's model X...We are collecting things like how long do you plan to stay parked, how many miles do you need at a minimum...

We've got the first row of 30x stations done, since that is all that will fit in a model s...next time we will finish the remaining 24x...More details on scheduling algorithms soon!

Last edited:

Cottonwood

Roadster#433, Model S#S37

Great work! Thanks for sharing!!

Where is this located and is the lot open to the public? I have driven my Model S to SoCal from CO twice and would love to visit on my next trip.

You should have a load test. Given the number of Model S's in SoCal, I bet that you could get enough volunteers to give the system a good test.

Are you publishing details of the design somewhere as a reference for others?

80 Amp J1772 Plugs/Cables are hard to find. Would you share your source?

Where is this located and is the lot open to the public? I have driven my Model S to SoCal from CO twice and would love to visit on my next trip.

You should have a load test. Given the number of Model S's in SoCal, I bet that you could get enough volunteers to give the system a good test.

Are you publishing details of the design somewhere as a reference for others?

80 Amp J1772 Plugs/Cables are hard to find. Would you share your source?

Zoltrix77

Member

As an electrician from Australia, I'm always quite amazed at how much conduit needs to be installed in the US. It seems as though cables anywhere need to be installed in conduit, is this correct? Does the wiring in conduit just have to be single insulated? Over here, that run through the parking lot (car park for me!) would most likely be double insulated cable on a suspended cable tray with no other protection. The cables down the walls would be in conduit for mechanical protection, but again, it would only be PVC conduit at the height shown in the pictures because it's not likely to be hit by a vehicle. Not many sparks have a lot of experience with metal conduit.

Here are some example pictures that I could find. You guys sure have it tough! I don't want to hijack the thread, but it's interesting for myself.

Here are some example pictures that I could find. You guys sure have it tough! I don't want to hijack the thread, but it's interesting for myself.

emchen

Member

Bravo! What a thing of beauty.

I drive the 210 freeway often...is it located in the parking structure on S Holliston? I would also be interested in stopping by for a quick charge and enjoy the campus for a bit.

I drive the 210 freeway often...is it located in the parking structure on S Holliston? I would also be interested in stopping by for a quick charge and enjoy the campus for a bit.

grichard

Member De-Luxe

@Cottonwood: It's open to the public, however, you have to pay for a parking pass from a nearby kiosk. Once we have our official grand opening I would love if a bunch of Teslas showed up so we could stress the system...not yet though! As for the design, we are still not sure if we are going to release that. 80A cable assemblies are from Tony@QuickChargePower.

@Zoltrix77: We were told it has to be in rigid conduit, and yes it was a pain in the ass to install all of that conduit.

@emchen: It's not in Holliston, but I am sure you can find it. =)

@Zoltrix77: We were told it has to be in rigid conduit, and yes it was a pain in the ass to install all of that conduit.

@emchen: It's not in Holliston, but I am sure you can find it. =)

We had our soft opening this week...and it was more EVs than we expected without announcing anything...I guess free electricity is easy to smell! there were teslas, i3s, i8, volts, cmax, prius...lots of plugin hybrids...most people stayed 4-8 hours of which charging was only 2-3 hours. This was around what we expected. In our next deployment(100+ stations) we will probably have both 40A and 80A stations, not just 80A. =)

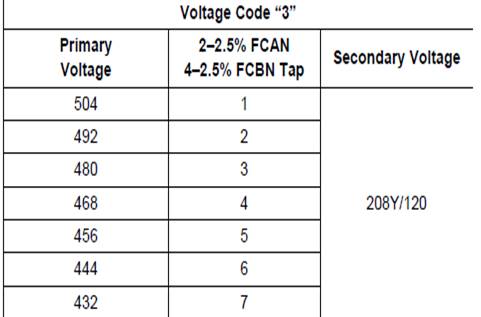

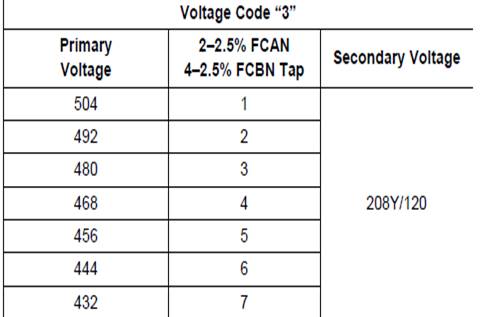

Due to the distance the transformer is from the electrical room ~300ft, 480v became 470v, which made the 208v secondary 200v. We had to change the input tap to compensate for that...Now we are on tap 6, which is providing 214v down at each station...which begs the question...if these cars can handle 240v, why wouldn't we just crank the 208v up to 230-240v? Anyone try this before? I don't see a drawback unless the primary side moves up significantly?

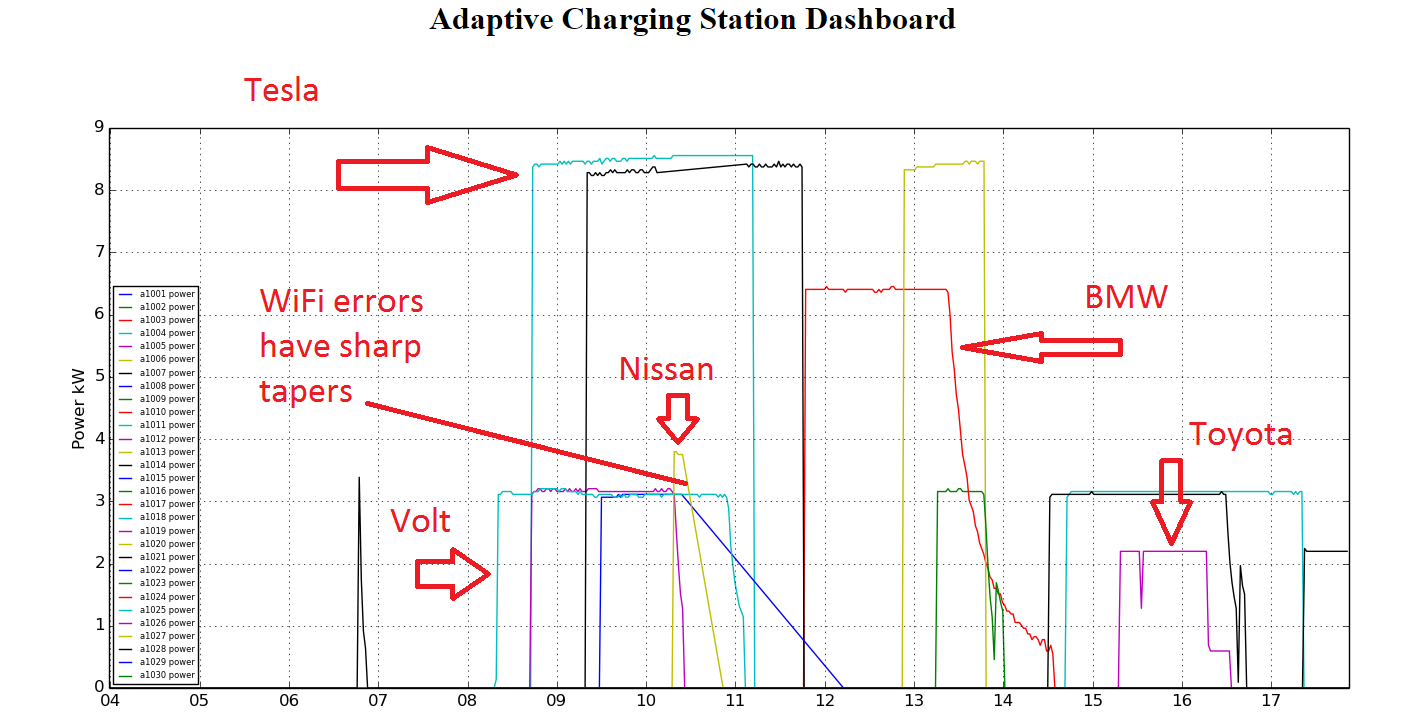

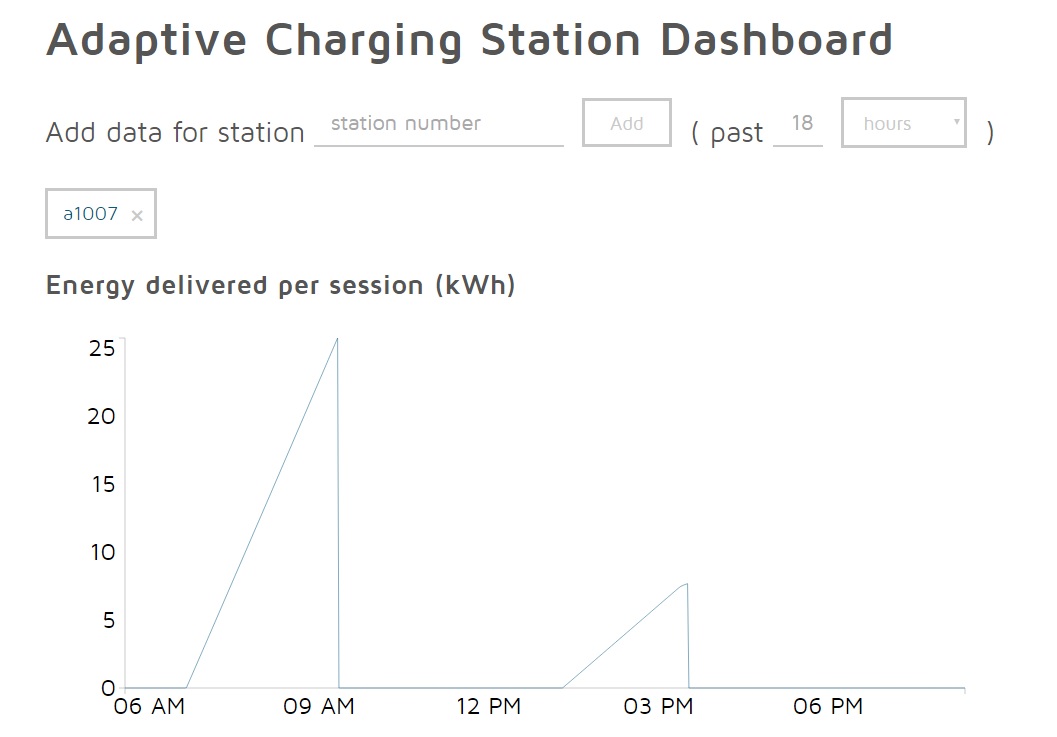

Here's a quick dashboard we threw together...interesting to see the different taper curves...we're limiting to 8.6kw right now, but will raise that up to 19kw soon.

Due to the distance the transformer is from the electrical room ~300ft, 480v became 470v, which made the 208v secondary 200v. We had to change the input tap to compensate for that...Now we are on tap 6, which is providing 214v down at each station...which begs the question...if these cars can handle 240v, why wouldn't we just crank the 208v up to 230-240v? Anyone try this before? I don't see a drawback unless the primary side moves up significantly?

Here's a quick dashboard we threw together...interesting to see the different taper curves...we're limiting to 8.6kw right now, but will raise that up to 19kw soon.

Cottonwood

Roadster#433, Model S#S37

Great work!!!

The nominal Voltage for J1772 L2 charging is 208-240 Volts, but we know that there is tolerance. I believe that the Tesla AC charger can take 100-250 Volts AC and versions can go up to 277 Volts nominal in Superchargers.

Let's do a little math on tolerances. If the input is 470 Volts and you use Tap 7, the output will be 470/432*208 or 226 Volts. Let's look at it another way, if the input rose to the highest this transformer expects or 504 Volts, then the output rises to 504/432*208 or 243 Volts, well within ranges normally seen by J1772 vehicles. I often see 250 Volts or very close at my Pagosa house when the Solar system is cranking out 20 kW to match the Tesla 20 kW load.

As long as there are no loads that actually expect 208 Volts, I say go for it. 9% faster charging is good for everyone! The only complication is that you will have to take the new output Voltage into account in your calculations for keeping the total kVA within limits on each transformer, but that should be easy.

I hope FlasherZ weighs in on this in terms of any possible code issues.

I can't wait to see results of a load test with active limiting to stay within your kVA limits. BTW, what are those limits?

Keep up the great work!

Due to the distance the transformer is from the electrical room ~300ft, 480v became 470v, which made the 208v secondary 200v. We had to change the input tap to compensate for that...Now we are on tap 6, which is providing 214v down at each station...which begs the question...if these cars can handle 240v, why wouldn't we just crank the 208v up to 230-240v? Anyone try this before? I don't see a drawback unless the primary side moves up significantly?

The nominal Voltage for J1772 L2 charging is 208-240 Volts, but we know that there is tolerance. I believe that the Tesla AC charger can take 100-250 Volts AC and versions can go up to 277 Volts nominal in Superchargers.

Let's do a little math on tolerances. If the input is 470 Volts and you use Tap 7, the output will be 470/432*208 or 226 Volts. Let's look at it another way, if the input rose to the highest this transformer expects or 504 Volts, then the output rises to 504/432*208 or 243 Volts, well within ranges normally seen by J1772 vehicles. I often see 250 Volts or very close at my Pagosa house when the Solar system is cranking out 20 kW to match the Tesla 20 kW load.

As long as there are no loads that actually expect 208 Volts, I say go for it. 9% faster charging is good for everyone! The only complication is that you will have to take the new output Voltage into account in your calculations for keeping the total kVA within limits on each transformer, but that should be easy.

I hope FlasherZ weighs in on this in terms of any possible code issues.

I can't wait to see results of a load test with active limiting to stay within your kVA limits. BTW, what are those limits?

Keep up the great work!

The nominal Voltage for J1772 L2 charging is 208-240 Volts, but we know that there is tolerance. I believe that the Tesla AC charger can take 100-250 Volts AC and versions can go up to 277 Volts nominal in Superchargers.

Let's do a little math on tolerances. If the input is 470 Volts and you use Tap 7, the output will be 470/432*208 or 226 Volts. Let's look at it another way, if the input rose to the highest this transformer expects or 504 Volts, then the output rises to 504/432*208 or 243 Volts, well within ranges normally seen by J1772 vehicles. I often see 250 Volts or very close at my Pagosa house when the Solar system is cranking out 20 kW to match the Tesla 20 kW load.

As long as there are no loads that actually expect 208 Volts, I say go for it. 9% faster charging is good for everyone! The only complication is that you will have to take the new output Voltage into account in your calculations for keeping the total kVA within limits on each transformer, but that should be easy.

The original Tesla chargers were marked 85-265V, so as you note they can pretty much work with anything. Due to a failure in a voltage regulation component, my home's been running at 255-256V over the past couple of weeks or so... I can confirm the car will charge at this voltage without a problem. Power company got it fixed today, we're back down to 245ish.

The real issue with using the other taps is that your L-N voltage can become dangerous if anyone wanted to use it. 226V L-L on the wye ends up becoming 130V L-N, which can be a bit too hot for some appliances. As long as no one ever intends to connect 120V loads to that transformer, then there's no issue with using the higher boost taps.

@Cottonwood: 2x 150kva transformers split 30x and 24x, I think we can run them close to 100%, but I am not exactly sure.

@FlasherZ: I'm surprised there is nothing in the code that requires +-10% of 208v. Good point on the L-N...looks like we will have to invest into some permanent signage on the panel...

- - - Updated - - -

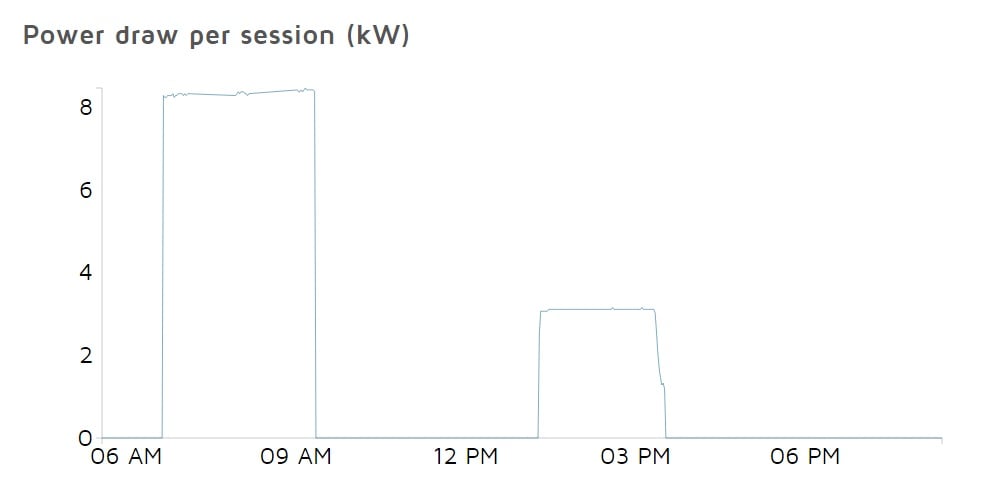

Cleaned up some of the graphs today...here's a sample station, I think a Tesla then a Volt or something...

Another view...energy delivered per session

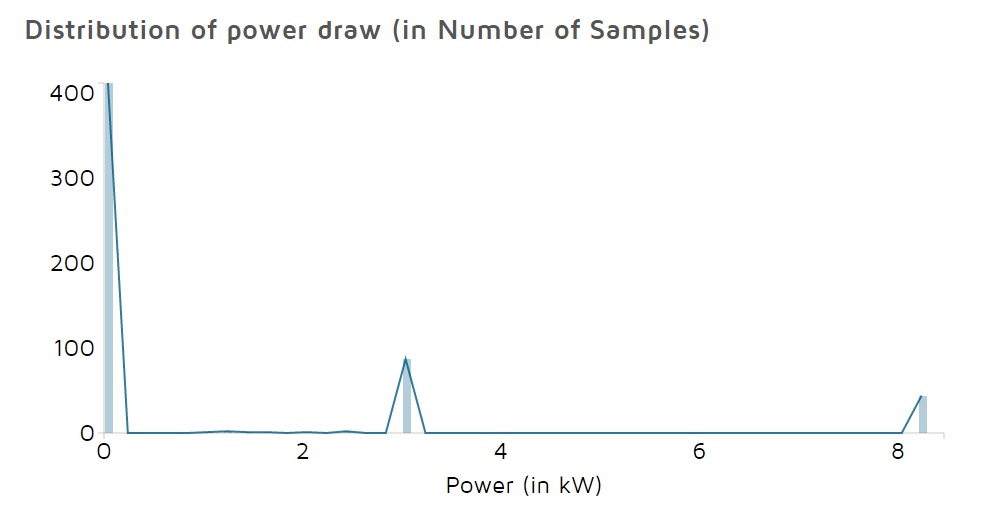

And finally a distribution...which I think is useful to see what are the max power from different cars are. Also, a good estimate for utilization, basically this station is spending to much time doing nothing!

@FlasherZ: I'm surprised there is nothing in the code that requires +-10% of 208v. Good point on the L-N...looks like we will have to invest into some permanent signage on the panel...

- - - Updated - - -

Cleaned up some of the graphs today...here's a sample station, I think a Tesla then a Volt or something...

Another view...energy delivered per session

And finally a distribution...which I think is useful to see what are the max power from different cars are. Also, a good estimate for utilization, basically this station is spending to much time doing nothing!

@FlasherZ: I'm surprised there is nothing in the code that requires +-10% of 208v. Good point on the L-N...looks like we will have to invest into some permanent signage on the panel...

The NEC doesn't have any provisions for standard voltage; it merely calls out target ranges for max voltage drop and standards for various voltage strata.

ANSI C84.1 calls out voltage standards, with 208V nominal calling out a "favorable" spec of 187-218V, and a "tolerable" spec of 180-220.

In this case, though, as long as you're using only L-L voltage and things are signed really well, I see no reason why you couldn't use the higher buck taps beyond that - because you know your application, and we don't know of a charger out there that handles 208V but not 240V.

We were told it has to be in rigid conduit, and yes it was a pain in the ass to install all of that conduit.

In the US, non-armored cables must not be exposed where they are "subject to physical damage". In residences, this is typically interpreted as anything below 2.5 meters or so. Commercial installations require even more protection.

One question for you, though - do you have a single circuit to every EVSE or are you sharing a small number of large circuits with multiple EVSE's? I saw that you said you were using #4 for 80A circuits (up to 64A charging current), but I didn't see one conduit per station there.

NEC 310.15(B)(3)(a) table shows the derating figure for number of current-carrying conductors. 4-6 is 80%, 7-9 is 70%, 10-20 is 50%. Each EVSE uses 2 current-carrying conductors - so if a single conduit supplied 5-10 stations, each one on an individual circuit, you'd need a wire capable of carrying 160A. That would be a 1/0 conductor for THHN2 (90 degC). How are you working with that limitation (it's a fairly big one in a garage, as you'd imagine, and I get asked that question a lot).

For this deployment we are using single circuits to each station. The circuits do share a common large 4 inch conduit/gutter before it branches out to 1 inch conduits for each station. An added bonus of flexible pilot signals is that if a station is too far away, we could just software the limit the station to the calculated capacity, like 68A instead of 80A.

For NEC 310.15(B)(3)(a), wouldn't it seem that 160A would be overkill?

For NEC 310.15(B)(3)(a), wouldn't it seem that 160A would be overkill?

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 2

- Views

- 2K

- Replies

- 560

- Views

- 196K

- Replies

- 229

- Views

- 122K