Invariably when discussion turns to a failing battery pack, the topic of module swapping comes up, so we thought it would be a good time to talk about CAC - Calculated Average Capacity - and why it's important.

In fact, if your talking to a shop about pack replacement/repair and they’re unable to provide you with the CAC for each and every brick in your pack, chances are your car will be back on a lift in the next 12 months, possibly sooner...

Measured in Amp hours (Ah), CAC is the single most important measure of your pack’s health. There can of course be a number of factors that may cause a pack to fail, but a well-balanced pack, even an older one, with a capacity delta less than 2% across each of the modules will continue to deliver years of safe, reliable power.

On the other hand, a poorly balanced pack will begin to exhibit less and less range, until finally it begins to fail and trigger a BMS_u018 alert, or stops working altogether. A poorly balanced pack is the result of one or more bricks in the pack deliverying less energy capacity than the others in the rest of the pack.

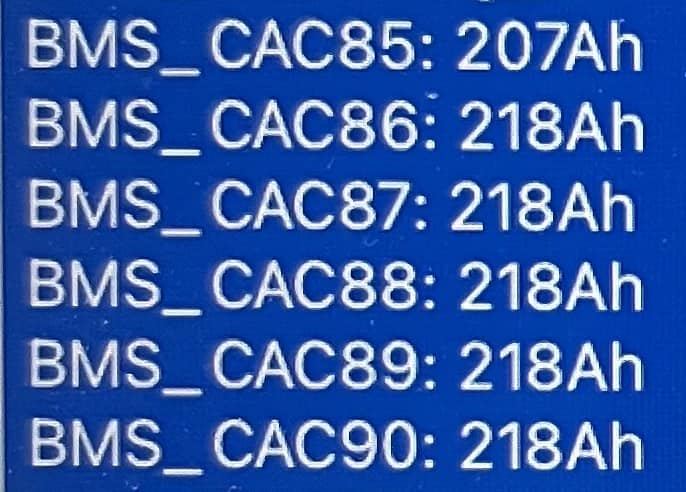

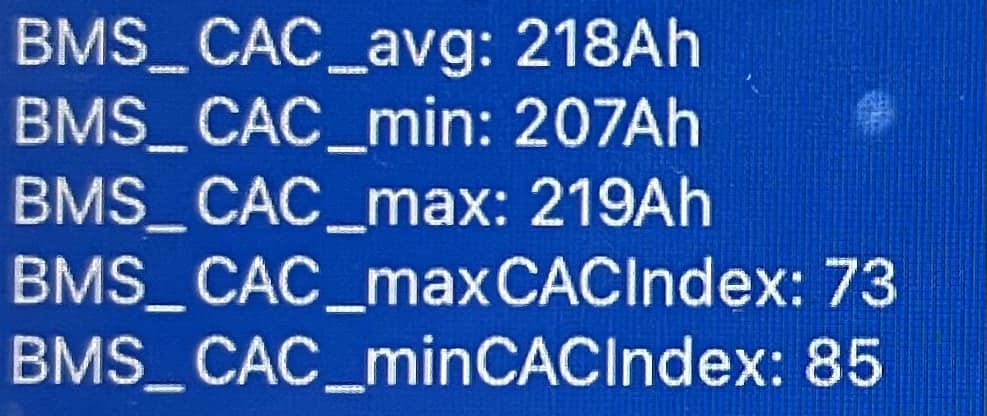

Take a look at the two screenshots below. It’s actually a textbook example of an otherwise healthy pack with a failing module. Brick 85 (located in Module #15) has begun to fail and is only able to deliver 207 Ah of energy, while the rest of the pack is delivering 218 Ah or more.

The result is a voltage imbalance in the pack that will accelerate the failure - continuing to charge weakened/imbalanced cells to 90% or more (while the rest of the pack sits comfortably at 80% SoC or less) simply accelerates their degradation relative to the rest of the pack and increases potential for overheating. none of these are ever good for a battery pack.

This is why capacity matching is so critical. Modules need to be balanced within 2%, or less! And if you can’t measure CAC at the brick level, then all bets are off, you're flying absolutely blind.

In fact, capacity matching is such an exacting requirement that Tesla, even with enormous pools of modules to choose from, no longer swaps modules in it’s reman packs - instead they convert them to a 350V 14-module pack. (full disclosure: Recell does the same). As a further datapoint, the longest we’ve seen a first generation Tesla reman last is about 30 months, most that we see last around 24 months. Of course, there may be others out there ("I have a friend whose cousin..."), but that’s consistently the longevity we, and others, have seen when it comes to module swapping. And if you can’t measure brick-level CAC, then it’s just like throwing darts at the wall.

So, will swapping in a new module get your Tesla back on the road? Sure, maybe, for a while. But as we always say, keeping it on the road is the hard part.

Remember CAC is King.

In fact, if your talking to a shop about pack replacement/repair and they’re unable to provide you with the CAC for each and every brick in your pack, chances are your car will be back on a lift in the next 12 months, possibly sooner...

Measured in Amp hours (Ah), CAC is the single most important measure of your pack’s health. There can of course be a number of factors that may cause a pack to fail, but a well-balanced pack, even an older one, with a capacity delta less than 2% across each of the modules will continue to deliver years of safe, reliable power.

On the other hand, a poorly balanced pack will begin to exhibit less and less range, until finally it begins to fail and trigger a BMS_u018 alert, or stops working altogether. A poorly balanced pack is the result of one or more bricks in the pack deliverying less energy capacity than the others in the rest of the pack.

Take a look at the two screenshots below. It’s actually a textbook example of an otherwise healthy pack with a failing module. Brick 85 (located in Module #15) has begun to fail and is only able to deliver 207 Ah of energy, while the rest of the pack is delivering 218 Ah or more.

The result is a voltage imbalance in the pack that will accelerate the failure - continuing to charge weakened/imbalanced cells to 90% or more (while the rest of the pack sits comfortably at 80% SoC or less) simply accelerates their degradation relative to the rest of the pack and increases potential for overheating. none of these are ever good for a battery pack.

This is why capacity matching is so critical. Modules need to be balanced within 2%, or less! And if you can’t measure CAC at the brick level, then all bets are off, you're flying absolutely blind.

In fact, capacity matching is such an exacting requirement that Tesla, even with enormous pools of modules to choose from, no longer swaps modules in it’s reman packs - instead they convert them to a 350V 14-module pack. (full disclosure: Recell does the same). As a further datapoint, the longest we’ve seen a first generation Tesla reman last is about 30 months, most that we see last around 24 months. Of course, there may be others out there ("I have a friend whose cousin..."), but that’s consistently the longevity we, and others, have seen when it comes to module swapping. And if you can’t measure brick-level CAC, then it’s just like throwing darts at the wall.

So, will swapping in a new module get your Tesla back on the road? Sure, maybe, for a while. But as we always say, keeping it on the road is the hard part.

Remember CAC is King.

Last edited: