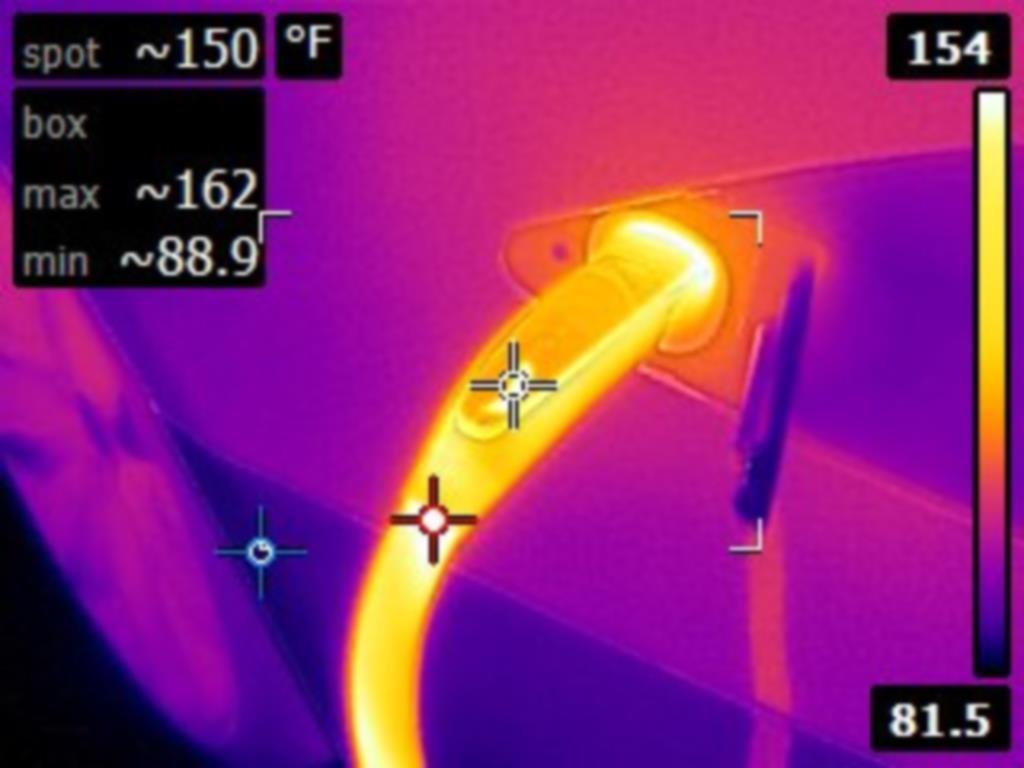

Tested out the replacement HPWC with pretty close results. Oddly enough the handle at the car was a bit cooler than my previous one, so, I'll go with it.

So, I wanted to get some good measurements of voltages at multiple points along the way. At 80A charging this is what I saw (this was in the middle of the day, no ToU metering at this location... voltages are easily 10V higher at night):

- 234V @ Model S Dash readout

- 236.0V @ junction inside HPWC heading towards car

- 236.4V @ 2AWG copper input to HPWC

- 238.2V @ Panel

This comes to about 4.2V @ 80A of resistive heating loss, or about 336 watts. Not negligible, but, my 2AWG run is roughly 30ft. The HPWC cable is 25ft, so, about 6.1 watts per foot average heat generation in the wiring. ~6.4W/ft in the HPWC->Car cable, ~5.76W/ft in my 2AWG cable... so, nearly the same resistive losses, which explains the warm conduit. No where near any unsafe temp, however.

336W may not seem like much, but it does add up in an insulated cable over time. At these currents, though, it is expected there will be some loss to heat unless we're talking about some ridiculous gauge wiring.

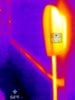

So, here is a baseline, a couple of minutes into charging @ 80A:

View attachment 55883View attachment 55884View attachment 55885View attachment 55886

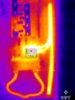

I checked back 30 minutes later:

View attachment 55887View attachment 55888View attachment 55889View attachment 55890View attachment 55891View attachment 55892View attachment 55893View attachment 55894View attachment 55895

And about 30 minutes later again:

View attachment 55896View attachment 55897View attachment 55898View attachment 55899View attachment 55900View attachment 55901View attachment 55902View attachment 55903

-----

So, some notes.

This time I left the protective plastic on the cover for the HPWC... I figure this would help with the FLIR cam a bit and not just register reflections. Seems to have worked, so, pics here with the cover on have the film on.

I also kept the cover installed during charging. I removed it each time I was taking pictures. Also, this is the brand new replacement HPWC that Tesla service mailed to me. I started the switch last night and finished the install this morning.

Next... that resistor scares me. Was almost 300F... and was already 275F at the start of the charge. It's just a resistor, but seems like it's under a pretty decent load for whatever reason...

There is some wiring inside that is well above 105C... not particularly safe for continuous use. And these pics are only after about an hour of charging... I hadn't charged for a couple of days since I received the replacement HPWC, but hadn't driven much... just about 100 miles.

In summary, my thoughts:

- I think resistive losses in the home wiring is acceptable.

- I think resistive losses in the HPWC->Car wiring is pretty close to acceptable, but probably would be an issue if a HPWC was under continuous use (for example, charging two Model S one after another...)

- To make the handle and external wiring cooler would require heavier (gauge and weight) wiring

- The wire is already pretty heavy, weight wise...

- The internals probably should be a bit beefier.

- At a minimum I'd say 2AWG wiring from the contactor to the junction to the charge cable.

- Have this spot sink the resistive heat that will linger here somewhere...

- The contactor itself is possibly underrated for this and might benefit from being a notch more heavy duty

- Perhaps a small cooling fan?

- Guess this would prevent weatherproofing, so maybe a design that includes some fins for a heat sink

- It will suffice for now.

I doubt we're going to see an overhaul anytime soon, so, it will suffice. I'm not afraid of it bursting into flames or anything, but, I am going to keep an eye on it.

Long term, since the warranty on the HPWC is only 1 year, I'll probably gut it and make an openEVSE type control board to put in there, a heavier contactor, and some heavier internal wiring. Also probably shorten the external cable slightly to fit my needs. Probably a PITA all together, but would make me feel better long term. Besides, can do plenty of cool stuff when you can program the controller yourself.

Long term I'd like to see Tesla completely redesign this thing and I'd buy an upgraded one in a heartbeat.