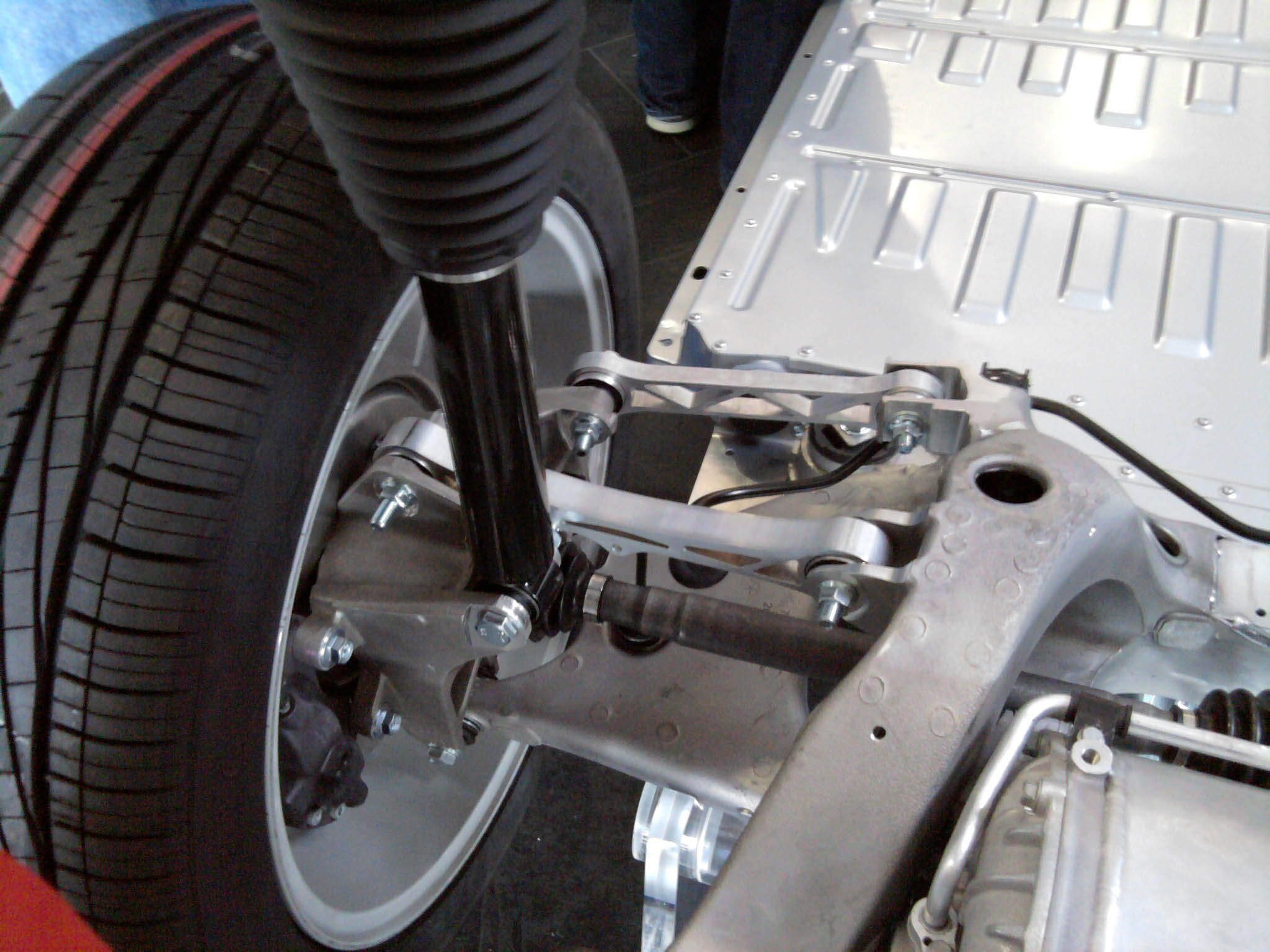

Looking at the image 3 posts prior we can conclude that this vehicle sustained a massive blow on the inside bottom of the wheel towards the outside, thus (sacrificially) folding and partially cracking the aluminum piece during compression. Likely the wheel or wheels that were discovered bent were also damaged during this event but they might be holdover issues from prior events. So conclude: the suspension skidded into a pothole or curb at a significant rate of speed. [armchair forensics]

This obvious sacrificial failure prevents the bending of other frame/suspension parts that could easily go undetected had the sacrificial part been made stronger. It is a passenger car and not an off-road racer, rock climber etc.

--

This obvious sacrificial failure prevents the bending of other frame/suspension parts that could easily go undetected had the sacrificial part been made stronger. It is a passenger car and not an off-road racer, rock climber etc.

--