Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

-

On today's TMC Podcast, we ask the question "What is the Tesla Cybercab?". Join us on YouTube live at 1PM and participate in the chat.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I purchased the EVMudFlaps in 2020 for our MY and yes it does require drilling but that sucker will stay on the car for good. It was a rock solid mud flap set and I used it for an entire year in Alaska including a long winter and those flaps exceeded my expectations. They look nice and are a perfect fit. They are on the pricier side but cheaper than Rally Armor. You will need a pivot screw driver piece in order to get it all installed but you do not need to remove any tires like someone mentioned a couple pages back. I will be purchasing them again for our MYP

My service appointment was pushed out to next friday. I will update you guys then.

These are the pictures of the bolt that was not coming out and the after picture showing the "nut" that the bolt goes into, but its cylindrical so it just spun with the bolt.

Also notice the 2nd hole without anything in there. It was the same on the other side. Is everyones like that?

View attachment 732320

View attachment 732321

So the mobile service technician came out, removed the underbelly plastic shield under the trunk and told me that the car needs to go to the body shop to have it repaired. The previous technician must not have put in the proper order as the 2nd technician brought a new underbelly but the nut needs to be "welded" on the car. If it wasnt a brand new tesla, i would be ok going to the hardware store and putting on a locking nut but figured i'll take it in to the service center and get it repaired the right way. sorry i dont have a real update but once I get it back from the body shop, i will update everyone.

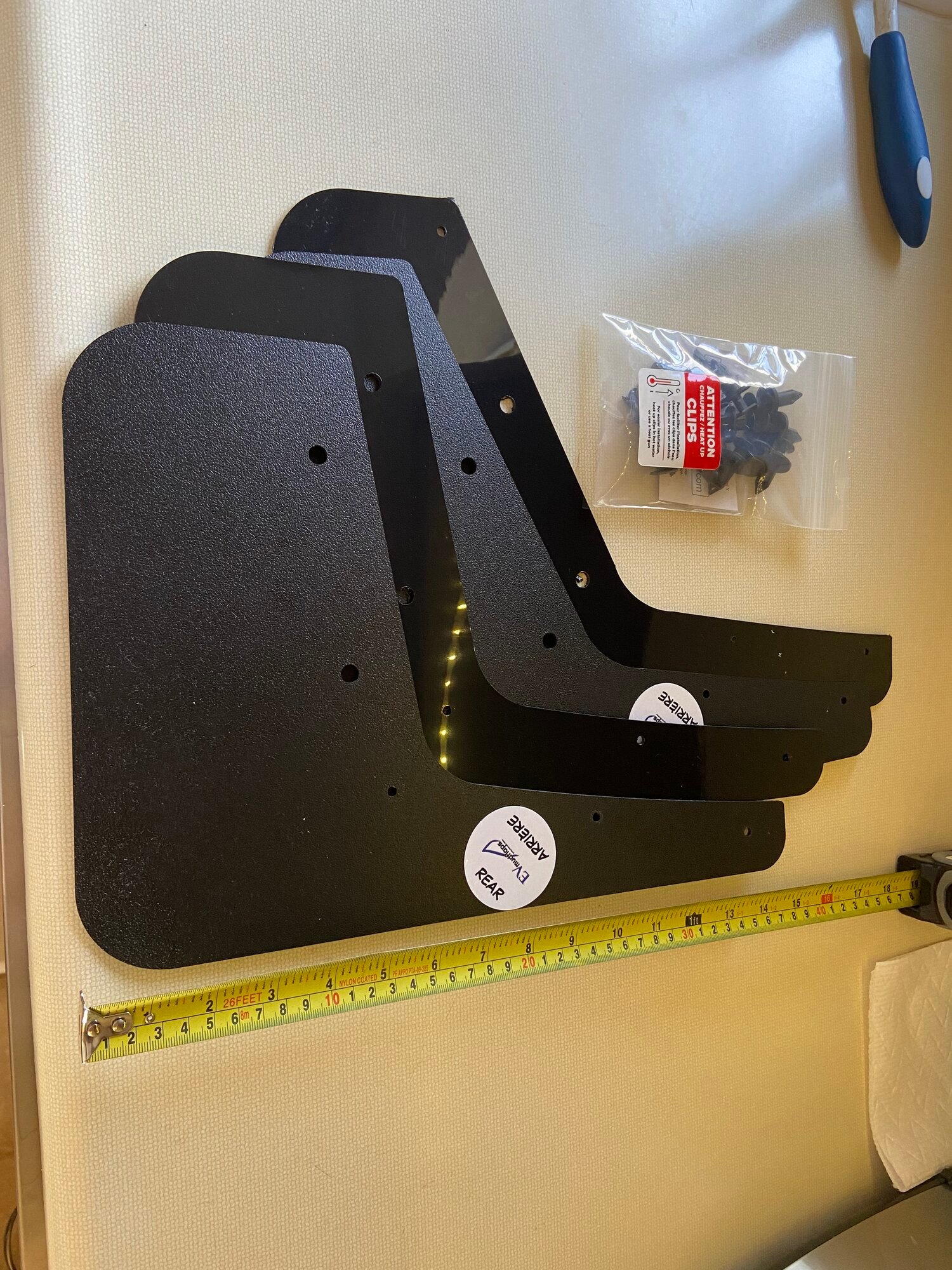

I purchased the mud flaps from EVmudflaps for my MYLR:

The process took about a half hour to gather up the tools, move the car, and put in the four flaps. Here are my experiences:

For the pop-in that went through metal on one of the rear flaps (step #7), I ended up trying 3 pop-ins before I got it to work. The kit includes extras. This isn't the kit's fault, it is just difficult to do; inserting the pop-in seems to push-back the plastic a little with-respect-to the metal so it isn't all the way in. A combination of pushing and twisting seemed to work, then the center pops in correctly with some leverage.

Milwaukee right-angle: https://www.amazon.com/dp/B07VYL7299

Small nail puller: https://www.amazon.com/dp/B07GXHRTRF

Here are some photos. The flaps are large, but they look fine on the car. I've already chrome deleted the emblems, and have ordered Rimetrix hubcaps for the wheels. So these sized flaps seem apropos.

Basically, this kit is expensive for just four flat plastic pieces with holes drilled and a bag of pop-ins and screws. However, everything is well made, fits well, is the right shape, the holes are in the right places, and I'm happy with it.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

The process took about a half hour to gather up the tools, move the car, and put in the four flaps. Here are my experiences:

- I did the procedure with the car on the ground with all of the wheels still attached and the wheels straight ahead

- A right-angle drill adapter is REQUIRED. His video shows a DeWalt but I have a Milwaukee.

- A small nail puller worked great. Probably much better than a screwdriver. I bought a small nail puller just for this.

- I heated up two cups of water in the microwave until boiling, then put the pop-ins in there and let them sit for 10 minutes. They sink.

- The textured side of each flap goes towards the rear of the car. They are textured on one side and smooth on the other.

- The front flaps have 3 vertical holes, the rear flaps have 2 vertical holes

- The hole for the rear flap that is in metal is a real pain to get in correctly.

- I used my DeWalt drill on torque setting #1 (the lowest) to drive the screws. It worked fine and didn't strip them.

- I did all of the pop-ins first on all four flaps, then I went back and did all of the screws.

- I also did the far screw on each of the two rear flaps. The video said that they were optional, but I think they are required. Once again, a right-angle adapter is required.

For the pop-in that went through metal on one of the rear flaps (step #7), I ended up trying 3 pop-ins before I got it to work. The kit includes extras. This isn't the kit's fault, it is just difficult to do; inserting the pop-in seems to push-back the plastic a little with-respect-to the metal so it isn't all the way in. A combination of pushing and twisting seemed to work, then the center pops in correctly with some leverage.

Milwaukee right-angle: https://www.amazon.com/dp/B07VYL7299

Small nail puller: https://www.amazon.com/dp/B07GXHRTRF

Here are some photos. The flaps are large, but they look fine on the car. I've already chrome deleted the emblems, and have ordered Rimetrix hubcaps for the wheels. So these sized flaps seem apropos.

Basically, this kit is expensive for just four flat plastic pieces with holes drilled and a bag of pop-ins and screws. However, everything is well made, fits well, is the right shape, the holes are in the right places, and I'm happy with it.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

SMR514

Member

Well, I'm late to the party.. My MYP is really stuck, and the mobile service could not get this screw out. I was helping him by holding a long pliers to try to hold the nut while turning the wrench, but no luck.

Sad part is, I didn't even have mud flaps to install at the time. I was just playing around with different(size) socket and it was unreasonably hard to turn it as if it was not threaded correctly. Then SNAP!

My car was only few days old, and below 100 miles at the time, and I do have other minor issues, so they scheduled me to come in for service.

It's currently just rattling around on its own, but I don't hear anything in the cabin for sure.

Sad part is, I didn't even have mud flaps to install at the time. I was just playing around with different(size) socket and it was unreasonably hard to turn it as if it was not threaded correctly. Then SNAP!

My car was only few days old, and below 100 miles at the time, and I do have other minor issues, so they scheduled me to come in for service.

It's currently just rattling around on its own, but I don't hear anything in the cabin for sure.

Well, I'm late to the party.. My MYP is really stuck, and the mobile service could not get this screw out. I was helping him by holding a long pliers to try to hold the nut while turning the wrench, but no luck.

Sad part is, I didn't even have mud flaps to install at the time. I was just playing around with different(size) socket and it was unreasonably hard to turn it as if it was not threaded correctly. Then SNAP!

My car was only few days old, and below 100 miles at the time, and I do have other minor issues, so they scheduled me to come in for service.

It's currently just rattling around on its own, but I don't hear anything in the cabin for sure.

View attachment 747520View attachment 747519

Trying holding the head with plyers and then use a small cut-off wheel to cut the thread (Dremel or other small hand-held). I don't know if this would actually work, but it seems like it might work. According to previous reports elsewhere, the alternative is to remove panels.

Or just ignore it until you actually need to remove that screw for some reason. The screw is still doing it job...

Likewise, the EVmudflaps that I installed (photos above) don't require removing that screw. So your photo is the poster child of why to avoid mud flips that require removing that screw

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

PackMan730

Member

These look like the rally armour ones.I purchased the mud flaps from EVmudflaps for my MYLR:

The process took about a half hour to gather up the tools, move the car, and put in the four flaps. Here are my experiences:

- I did the procedure with the car on the ground with all of the wheels still attached and the wheels straight ahead

- A right-angle drill adapter is REQUIRED. His video shows a DeWalt but I have a Milwaukee.

- A small nail puller worked great. Probably much better than a screwdriver. I bought a small nail puller just for this.

- I heated up two cups of water in the microwave until boiling, then put the pop-ins in there and let them sit for 10 minutes. They sink.

- The textured side of each flap goes towards the rear of the car. They are textured on one side and smooth on the other.

- The front flaps have 3 vertical holes, the rear flaps have 2 vertical holes

- The hole for the rear flap that is in metal is a real pain to get in correctly.

- I used my DeWalt drill on torque setting #1 (the lowest) to drive the screws. It worked fine and didn't strip them.

- I did all of the pop-ins first on all four flaps, then I went back and did all of the screws.

- I also did the far screw on each of the two rear flaps. The video said that they were optional, but I think they are required. Once again, a right-angle adapter is required.

For the pop-in that went through metal on one of the rear flaps (step #7), I ended up trying 3 pop-ins before I got it to work. The kit includes extras. This isn't the kit's fault, it is just difficult to do; inserting the pop-in seems to push-back the plastic a little with-respect-to the metal so it isn't all the way in. A combination of pushing and twisting seemed to work, then the center pops in correctly with some leverage.

Milwaukee right-angle: https://www.amazon.com/dp/B07VYL7299

Small nail puller: https://www.amazon.com/dp/B07GXHRTRF

Here are some photos. The flaps are large, but they look fine on the car. I've already chrome deleted the emblems, and have ordered Rimetrix hubcaps for the wheels. So these sized flaps seem apropos.

Basically, this kit is expensive for just four flat plastic pieces with holes drilled and a bag of pop-ins and screws. However, everything is well made, fits well, is the right shape, the holes are in the right places, and I'm happy with it.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

View attachment 736550

View attachment 736551

View attachment 736552

View attachment 736553

View attachment 736554

These look like the rally armour ones.

They are somewhat similar, but no logo and the installation process was easier for me than what is shown in the Rally Armour installation videos.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

How do you mean? Do you really have to use that angle tool?They are somewhat similar, but no logo and the installation process was easier for me than what is shown in the Rally Armour installation videos.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

boriska007

New Member

I was lucky one of the nut just fell off when I was trying to put the bolt back, the other one fell got lose when I was trying to unscrew it, I eventually had to cut it with a sawMy car had a 2nd hole without anything there also.

How do you mean? Do you really have to use that angle tool?

Without the angle tool, I think that I would have needed to remove the tire to get to that inside screw. The angle tool made it trivial, so I didn't attempt the alternative.

Scott

--

MYLR | Red ext | White int | 19" | 5 seats | tow | no FSD | made/delivered Oct 2021

SweetT23

New Member

Would love to see a photo or video of how you removed the bolt with a flathead screwdriver. My weld broke today and now the bolt is just hanging there. Kind of a bummer. Since it broke I’m now afraid to do anything else to my brand new model y. 2022 btw, only two weeks old. : (Quick summary for those that dont know about the rear door damage caused by the front wheel kickback.

Everything that your front wheels drive over have this kind of trajectory:

This means little tiny rocks are damaging your paint:

A really bad example (from a post here on TMC), all the white spots are chipped off paint:

I live in Southern California, Ive had my Model Y for a bit over a year (June 2020), we've had rain less than 5 times in the entire time Ive owned the car, our roads see so much traffic that all of the debris, rocks, sand is pushed off the road. Where I live roads are excellent (seems like they repave instead of trying to cover cracks). That is all to say that under my driving conditions I dont have any visible/audible rocks/sand etc... yet my experience in a year is about the same as the blue Model Y (I do have ceramic coat too, so that wont save you). Its equal on both sides. Luckily its light enough to where some buffing compound and a rotary buffing tool got most of it out (with a bit of Dr Colorchip).

The issue is bad enough that Tesla started to offer a PPF kit for that area ($50 but seems to be out stock most of the time), and in some regions they even install it at factory before shipping. - Model Y Paint Protection Film

So then, what is the solution? I see this as a 2 step thing. You can do the PPF, either at any reputable shop, shouldnt be expensive, Tesla's price + labor. You can get Tesla's kit and DIY it, or get a kit from some other 3rd party, RPM Tesla, Abstract Ocean etc...

But while this will protect the door paint (hopefully), it wont protect the plastic right under the door. That thing is actually pretty rough (if you run your hand along it). So for that you would get mud flaps. Tesla offers a set for the front only. Or you can go 3rd party and usually for the same price as Tesla's get a set for all 4 wheels. Do your own research but Tesla's mud flaps are skinny and long, they wont clear some speed bumps and after using them for a few months you will notice that they wont be straight down anymore. In my opinion not great. But do your own research.

Mud flaps should protect the plastic and the door, but for extra safety you can also do PPF on that spot. (I am doing both). Mud flaps will stop most things, and if anything makes through the PPF hopefully will absorb.

Now, lets talk about the rear mud flaps. This is not something you need to worry about with Tesla's mud flaps, since they only give you the two front ones so you wont be installing anything on the back. Of course you can just do the front install on 3rd party ones as well and not worry about the back, this also means you dont need to worry about it.

But if you do back mud flaps install, a lot of the 3rd party ones utilize a 10mm bolt behind the rear wheel to attach one of the 3 points (front mud flaps only use the plastic clips and back use 2 plastic clips plus the bolt).

The issue is that some Teslas (from what I understand early ones) have an issue with that bolt. The nut that the bolt screws into is (was?) spot welded poorly. In a lot of cases in an attempt to get this bolt loose or tighten the weld breaks and now you have a spinny bolt you cant remove. In my case the weld was actually broken AT factory when they tightened it, it was tight but spun without unscrewing (Rear Left). I removed surrounding clips and used a flat head screwdriver to apply pressure against the nut in order to prevent it from spinning while using 10mm ratchet to remove the bolt. No problem. Here is what they look like (bolt and the broken off nut):

Now what? Well, two ways to go from here.

One - Attach it: disassemble the whole back to get to the metal frame and spot weld it back. OR if you dont have a means to weld you could use something like a 2 part epoxy that is labeled for Metal. This doesnt need to be an insane bond, and in all honesty 2 part epoxy after curing will probably be stronger than the factory weld as it will snap off with slightest bump, you just need the weld to be strong enough to tighten the screw back in.

Two - Use a clip. This is the route I went, from my perspective the weld was broken before my car left the factory, so all that screw/nut were doing was a compression hold against each other, something a clip does just as well. Additionally the mud flap "hug" around gives more structure to that piece of the car as it now supports it from the bottom. AND most importantly its not clear to me if Tesla started with clips and then went to bolts, or started with bolts then went with clips for that location (I am leaning for the latter since I have one of the first ones and it has bolts). But if its the latter that means most Y's out there have a clip in that spot anyways. There are bolts next to that spot (and more clips).

The clip goes perfectly into that spot, the slot where weld was is round, so its perfect. Here is comparison Tesla's clip and 3rd party clip, in this case Abstract Ocean (where I got the mud flaps and PPF from). They are longer and hold on just as well as a bolt.

So, what is the conclusion. Lets do it as a TLDR:

TLDR: Get mud flaps or rear door PPF or both (see pics above why). Dont be afraid of the bolt on the mud flaps. Chances are it will unscrew just fine. And if not, dont hacksaw it, use flathead screwdriver to apply pressure and undo it. Then use a clip in it's place. My mud flaps came with 2 extra clips just for these spots (probably because newer models have clips there anyways?).

imgur.com

Discover the magic of the internet at Imgur, a community powered entertainment destination. Lift your spirits with funny jokes, trending memes, entertaining gifs, inspiring stories, viral videos, and so much more from users.imgur.com

PS - I guess there is the other option, to not give a heck and just drive the car. We are lucky that the body is aluminum and wont rust.

Daludidi

Member

This happened on my one week old 22 MY as well.Would love to see a photo or video of how you removed the bolt with a flathead screwdriver. My weld broke today and now the bolt is just hanging there. Kind of a bummer. Since it broke I’m now afraid to do anything else to my brand new model y. 2022 btw, only two weeks old. : (

I don't know how anyone got the broken metal piece out with a screwdriver applying pressure, I resorted to holding the top side with long pliers then used a grinder to cut off the bolt head to pull it through.

So with Utah roads being absolutely horrendous, I'm seriously considering putting the mudflaps on. That being said, I see a lot of people saying their MYP came with mudflaps installed (as well as PPF). Has anyone figured out who qualifies for mudflaps?

Some Northern states bordering Canada.So with Utah roads being absolutely horrendous, I'm seriously considering putting the mudflaps on. That being said, I see a lot of people saying their MYP came with mudflaps installed (as well as PPF). Has anyone figured out who qualifies for mudflaps?

yyssjj33

Member

I just got my Model Y on 5/3/2022, have found the exact same loosen bolt on rear left when I was trying to install rear mud flap. It's just annoying that the bolt just hanging there, cannot be either tighten or screw off. Had requested a service, don't know if it's fully covered

Midnightsun

Active Member

I was also an early adopter of the EV mud flaps. Rock solid and work very well. Here is another 18 page thread on the subject. Why a Y Needs Mud Guards/Flaps

Ritzcarlton123

Member

I have Bomely mud guards via Amazon on my MYP. I’ve noticed they stopped sitting flush and there’s a gap for both front mud guards.

Anyone have a solution for this? Or is there a different brand that doesn’t have this issue?

beemerphile

Member

Web site rallyarmor.com flags as not secure. Not a fan of credit card transactions over non-secure sites. Any other sources available for these?I agree. Rally Armor Mud Flaps are fantastic and super easy to install.

Similar threads

- Replies

- 24

- Views

- 10K

- Replies

- 0

- Views

- 2K

- Replies

- 23

- Views

- 9K

- Replies

- 5

- Views

- 4K

- Replies

- 6

- Views

- 6K