Yesterday I worked with a local shop to remove all six brake calipers so they can be shipped to Armortech Powder Coating in Florida to be powder coated (see this thread). Together all six (two each front and rear and the two parking brake calipers) weigh about 35 pounds.

Thinking a few tech geeks like me would be interested, I took photos as the work proceeded. We clipped off the brake fluid hoses to minimize fluid leakage. Worked like a charm. As they're attached to the suspension mechanism with only two bolts, the main calipers are quite easy to remove. The two parking brake calipers are another story. More about that below.

Here's one of the front calipers. The peeling G2 paint can easily be seen here and in the other photos as well.

Here's the back side with the pads still in place.

Here's shot of the underside with the pads removed.

Here's the back side that one never sees when they're on the car. Note the brembo label.

In the shot below, the two pistons are visible. Fortunately, they don't have to be removed for Armortech's powder coating work.

The pads on parking brake calipers are driven by a screw-drive electric motor which is actuated when the car is place in Park. As there's not much room in the wheel well to work, they require more hand work and steps to remove. First the electrical connector has to be removed. It plugs into the receptacle on the far right in the photo below. Then the two bolts that hold the caliper to the rear suspension mechanism have to be removed. Here's a shot of the underside of the removed parking brake caliper. The motor is on the right side. Note the set screw in the center. It holds the sleeve for the piston in place. For power coating, the motor, which has a plastic housing, has to be removed.

In the photo below the four screws holding the motor onto the caliper are being removed. Note the brembo label and the peeling G2.

The underside of the parking brake caliper. Note the two pads which squeeze on the brake rotor when the motor drives them together.

Here the motor is being removed from the parking brake caliper.

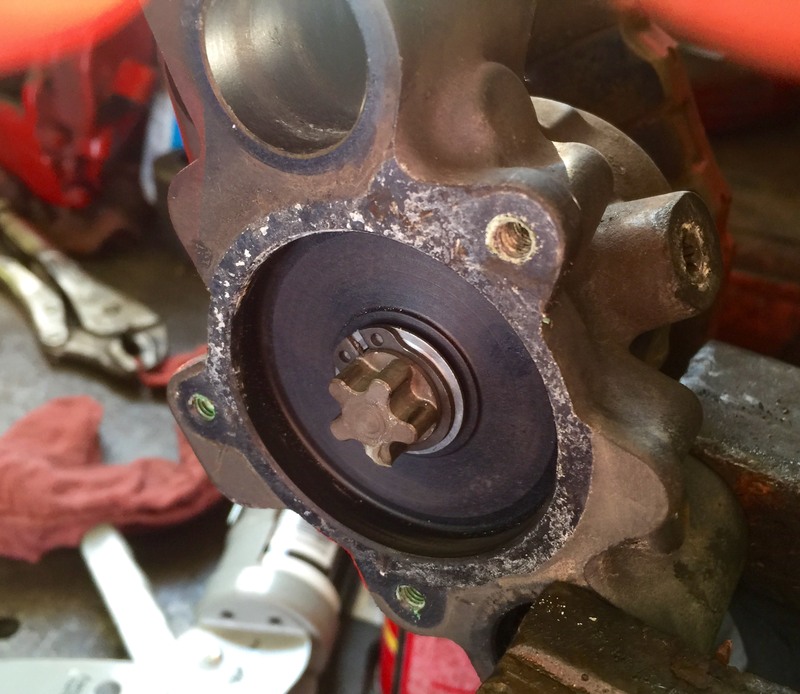

A detail of the piston drive gear head. When it turns clockwise the piston tightens the pads on the rotor. It all happens very quickly with very little movement of the pads necessary.

With the parking calipers unplugged the dash display shows a warning fault in the upper left side.

Finally, here's a naked front rotor with the calipers removed. Note the nearly pristine condition of the outer hat around the bolts, which was painted with silver epoxy when the calipers were painted with G2. That paint has proven far more durable than the G2.

Rolling the car out of the garage with no brakes of any kind scared the hell out of me, but Jeff and Richard at Wise Automotive in Timonium, MD, where all of this work was done this morning, did it with aplomb. It was second nature to them and no problem. They arranged for it to be plugged in to a 120v power source so the battery's charge is maintained during the week I'll be in Germany.

The newly powder coated calipers will be delivered back to Wise Automotive on December 14 and be reinstalled that day. I return from Germany the day before so I'll only be without the car for one day.

Thinking a few tech geeks like me would be interested, I took photos as the work proceeded. We clipped off the brake fluid hoses to minimize fluid leakage. Worked like a charm. As they're attached to the suspension mechanism with only two bolts, the main calipers are quite easy to remove. The two parking brake calipers are another story. More about that below.

Here's one of the front calipers. The peeling G2 paint can easily be seen here and in the other photos as well.

Here's the back side with the pads still in place.

Here's shot of the underside with the pads removed.

Here's the back side that one never sees when they're on the car. Note the brembo label.

In the shot below, the two pistons are visible. Fortunately, they don't have to be removed for Armortech's powder coating work.

The pads on parking brake calipers are driven by a screw-drive electric motor which is actuated when the car is place in Park. As there's not much room in the wheel well to work, they require more hand work and steps to remove. First the electrical connector has to be removed. It plugs into the receptacle on the far right in the photo below. Then the two bolts that hold the caliper to the rear suspension mechanism have to be removed. Here's a shot of the underside of the removed parking brake caliper. The motor is on the right side. Note the set screw in the center. It holds the sleeve for the piston in place. For power coating, the motor, which has a plastic housing, has to be removed.

In the photo below the four screws holding the motor onto the caliper are being removed. Note the brembo label and the peeling G2.

The underside of the parking brake caliper. Note the two pads which squeeze on the brake rotor when the motor drives them together.

Here the motor is being removed from the parking brake caliper.

A detail of the piston drive gear head. When it turns clockwise the piston tightens the pads on the rotor. It all happens very quickly with very little movement of the pads necessary.

With the parking calipers unplugged the dash display shows a warning fault in the upper left side.

Finally, here's a naked front rotor with the calipers removed. Note the nearly pristine condition of the outer hat around the bolts, which was painted with silver epoxy when the calipers were painted with G2. That paint has proven far more durable than the G2.

Rolling the car out of the garage with no brakes of any kind scared the hell out of me, but Jeff and Richard at Wise Automotive in Timonium, MD, where all of this work was done this morning, did it with aplomb. It was second nature to them and no problem. They arranged for it to be plugged in to a 120v power source so the battery's charge is maintained during the week I'll be in Germany.

The newly powder coated calipers will be delivered back to Wise Automotive on December 14 and be reinstalled that day. I return from Germany the day before so I'll only be without the car for one day.

Last edited: