In preparation for my Model S I have undertaken some extensive garage modification. Our primary 2 car garage is attached to our barn which houses 3 additional bays for car storage. The two car garage was serviced by two eight foot wide wooden garage doors with a center post that bifurcated the garage. These garage doors were always a bit too narrow as we have to make a 90 degree right turn into the garage from our driveway. Over the years, a few side mirrors have departed due to operator negligence as well.

When I looked at the specification of the Model S, I quickly realized that it was just about 2" wider than my Volvo XC-60 SUV so a bad situation was going to become even worse. This Spring I inspected the two garage doors which were made of raised panel wood and realized that they had seen better days. So I developed a plan to replace the two doors with one large 17 foot wide door and eliminate the center post. This project started in late March, and with the help of a few friends who were very skilled carpenters, we were able to tear down the old doors, tracks and center post and order an engineered header to support the wider opening. Here is a picture of the work in progress and the finished result.

The next step was the planning for the home charging system for the P90D. Here we had a greater problem... our barn was serviced by an underground branch of 120V 15 AMPs from the late 1930's. Old stuff. Also the span was long and to extend new electricity from the house to the barn would require extensive digging. Disruption of walkways and perennial flower beds would be considered a big negative by my wife and the expense to do so was very dear.

So thinking and thinking I came upon the idea to run a totally new electrical service to the barn complex. Estimates were solicited from 4 electrical contractors and as you would expect responses were all over the place, some being 2X the cost of the others. I went with a young electrician who was the best listener and who had great references from friends.

The plan was a 200 AMP service to a new Square D QO panel. Ground rods would provide ground and the electric company was called in to do a site inspection and approve the service. The electric utility engineer put in a work order to run new wires to my utility pole right near the barn.... here is a picture of that .....

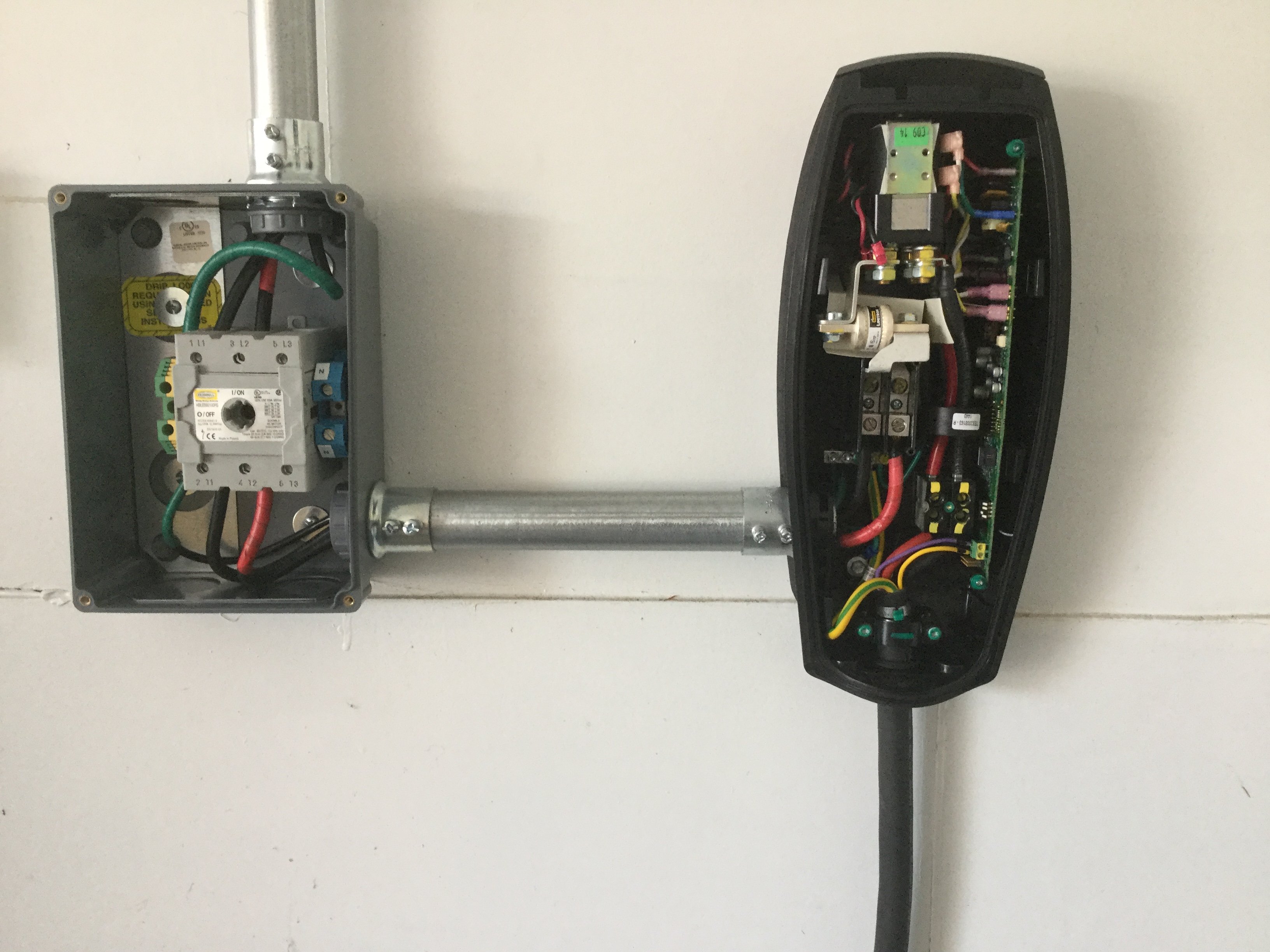

Afterward the electrician contacted the Town Engineer and pulled the necessary permits and then work quickly began.... here are a few pictures of the HPWC and the 14-50R which would be used as a backup should the HPWC ever fail...

The outlets and the 100AMP switch are all Hubble electronics and all work is in conduit.

At present the HPWC is not powered on as we do not have the electricity turned on.

Tomorrow, the Town Inspector will come and inspect the electrician's work and then put in the order for the Utility company to turn on the power....

Much thanks to Forum Member FLASHERZ who helped me with the specifications for the wiring!

What's Next....??

Ordering the P90D in December for a late March Delivery.... Stay Tuned Amigos...

When I looked at the specification of the Model S, I quickly realized that it was just about 2" wider than my Volvo XC-60 SUV so a bad situation was going to become even worse. This Spring I inspected the two garage doors which were made of raised panel wood and realized that they had seen better days. So I developed a plan to replace the two doors with one large 17 foot wide door and eliminate the center post. This project started in late March, and with the help of a few friends who were very skilled carpenters, we were able to tear down the old doors, tracks and center post and order an engineered header to support the wider opening. Here is a picture of the work in progress and the finished result.

The next step was the planning for the home charging system for the P90D. Here we had a greater problem... our barn was serviced by an underground branch of 120V 15 AMPs from the late 1930's. Old stuff. Also the span was long and to extend new electricity from the house to the barn would require extensive digging. Disruption of walkways and perennial flower beds would be considered a big negative by my wife and the expense to do so was very dear.

So thinking and thinking I came upon the idea to run a totally new electrical service to the barn complex. Estimates were solicited from 4 electrical contractors and as you would expect responses were all over the place, some being 2X the cost of the others. I went with a young electrician who was the best listener and who had great references from friends.

The plan was a 200 AMP service to a new Square D QO panel. Ground rods would provide ground and the electric company was called in to do a site inspection and approve the service. The electric utility engineer put in a work order to run new wires to my utility pole right near the barn.... here is a picture of that .....

Afterward the electrician contacted the Town Engineer and pulled the necessary permits and then work quickly began.... here are a few pictures of the HPWC and the 14-50R which would be used as a backup should the HPWC ever fail...

The outlets and the 100AMP switch are all Hubble electronics and all work is in conduit.

At present the HPWC is not powered on as we do not have the electricity turned on.

Tomorrow, the Town Inspector will come and inspect the electrician's work and then put in the order for the Utility company to turn on the power....

Much thanks to Forum Member FLASHERZ who helped me with the specifications for the wiring!

What's Next....??

Ordering the P90D in December for a late March Delivery.... Stay Tuned Amigos...