We know that Tesla's paint shop is ready to paint 500k bodies, so it appears it's ready to paint Model 3. What I wonder is if there are significant differences between painting steel and aluminum which would require two separate paint shops. If yes, than we can be pretty certain that Model 3 will be aluminum as well.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BrianC

Member

Aluminum will cost way too much to keep the car at 35k. You cant have a costly battery pack and aluminum and a nicely teched up car for that small of a price. Steel/plastic parts body with fabric seats for a base model for sure.

Bangor Bob

Member

Questions we're not really able to answer, but which Tesla likely is figuring out right now: How much of the cost of an Audi A4 (comparable aluminum-intensive benchmark for the Model 3 starting at $35,900) made up of the drivetrain vs. the aluminum-intensive body? How much battery capacity is saved to hit target range by using aluminum, and is that cheaper than using (and tooling up for) steel? Does going with aluminum for the 3 help them get better pricing for aluminum on the battery packs, S and X - increasing margins there?

Last edited:

Feh. My 6 year old pickup has an AL hood. I think this "AL is too expensive" stuff is overblown. If Chevy can do it, Tesla can.

Maybe the chassis/unibody won't be AL, but the panels could be.

I've owned a couple of Saturns way back when. The plastic body panels worked well.

Frankly, I think they could be plastic/steel/aluminum, take your pick.

Maybe the chassis/unibody won't be AL, but the panels could be.

I've owned a couple of Saturns way back when. The plastic body panels worked well.

Frankly, I think they could be plastic/steel/aluminum, take your pick.

MassModel3

Member

And one of the nice things about the Saturn was that it didn't easily dent or ding because if it got hit the panel would just pop back out. You might get a scrape or a crack in the paint or the topcoat, but that was the worst of it. I think if the 3 had plastic body panels, I'd be okay with that. It would certainly make for easier repairs by places other than expensive Tesla-approved body shops. But the underlying frame would need to be slightly beefed up because steel or aluminum panels are part of what provides impact protection -- plastic not so much.

Bangor Bob

Member

One more data point. Ford F150. As of 2015, aluminum body, steel ladder frame. Starting MSRP, $26615.

Eventual annual volume is similar.

Eventual annual volume is similar.

phigment

Member

I've owned a couple of Saturns way back when. The plastic body panels worked well.

Wasn't one of the problems with plastic panels the amount of thermal expansion? Large gaps had to be left between panels. I imagine this wouldn't be ideal for drag coefficient or looks.

If Ford can make a decent profit on an aluminum F150, I am thinking that Tesla can do the same on the Model 3.

Tesla already knows how to make the panels out of aluminum and they have spent a lot of time perfecting welding and bonding with aluminum.

A lighter car means that the battery pack can be smaller than with a heavier car and the batteries are still going to a major cost component. I say go with what you know.

Tesla already knows how to make the panels out of aluminum and they have spent a lot of time perfecting welding and bonding with aluminum.

A lighter car means that the battery pack can be smaller than with a heavier car and the batteries are still going to a major cost component. I say go with what you know.

I think the added cost of aluminum is overstated but then what do I know.

My guess is aluminum battery pack with steel body which is a reasonable compromise between weight and cost.

Would also make insurers happy since it would reduce repair costs which would should help keep insurance premiums lower.

Another case for some steel from Tesla VP of engineering Chris Porritt:

“I expect there will be very little carry-over. We’ve got to be cost-effective. We can’t use aluminium for all the components.”

http://gas2.org/2014/07/01/tesla-model-e-will-built-mostly-steel-priced-realistically/

My guess is aluminum battery pack with steel body which is a reasonable compromise between weight and cost.

Would also make insurers happy since it would reduce repair costs which would should help keep insurance premiums lower.

Another case for some steel from Tesla VP of engineering Chris Porritt:

“I expect there will be very little carry-over. We’ve got to be cost-effective. We can’t use aluminium for all the components.”

http://gas2.org/2014/07/01/tesla-model-e-will-built-mostly-steel-priced-realistically/

Last edited:

stopcrazypp

Well-Known Member

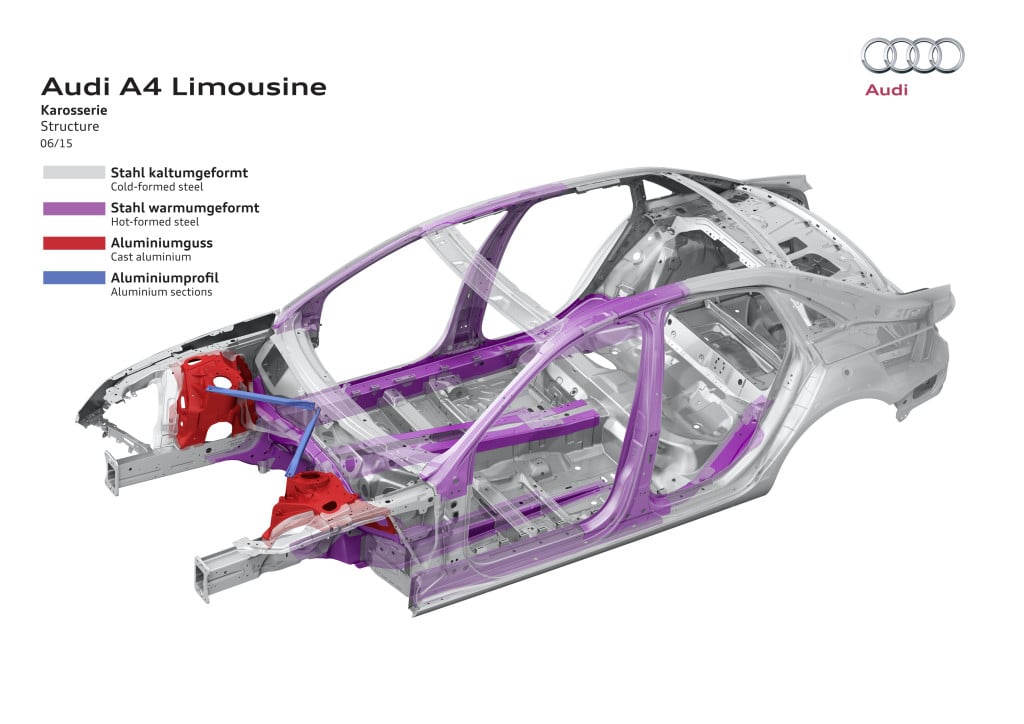

A4 is aluminum intensive, but still far less aluminum than the Model S for example. Most of it is steel, esp. the chassis:Questions we're not really able to answer, but which Tesla likely is figuring out right now: How much of the cost of an Audi A4 (comparable aluminum-intensive benchmark for the Model 3 starting at $35,900) made up of the drivetrain vs. the aluminum-intensive body? How much battery capacity is saved to hit target range by using aluminum, and is that cheaper than using (and tooling up for) steel? Does going with aluminum for the 3 help them get better pricing for aluminum on the battery packs, S and X - increasing margins there?

http://www.repairerdrivennews.com/2...-264-6-pounds-lighter-includes-more-aluminum/

I suspect the Model 3 will be similar.

Several people at Tesla have said the Model 3 will make much more use of steel. I have seen comments that it will have little to no aluminum.

There are differences with working steel and aluminum. Steel is more durable and doesn't develop cracks that can propagate like aluminum. Pure aluminum is much softer than steel, but aircraft aluminum alloys can be harder, though much much more expensive. I don't think anybody is using much aircraft aluminum in cars. Purer alloys of aluminum are much more corrosion resistant than steel, which is an advantage. Of course steel, being harder doesn't get damaged as easily and is usually cheaper to repair.

I don't think there are major differences painting the two metals.

There are differences with working steel and aluminum. Steel is more durable and doesn't develop cracks that can propagate like aluminum. Pure aluminum is much softer than steel, but aircraft aluminum alloys can be harder, though much much more expensive. I don't think anybody is using much aircraft aluminum in cars. Purer alloys of aluminum are much more corrosion resistant than steel, which is an advantage. Of course steel, being harder doesn't get damaged as easily and is usually cheaper to repair.

I don't think there are major differences painting the two metals.

Aluminum is much harder to paint than steel. I would imagine that each metal would need to undergo different treatment method such as accid bath and probably paint itself is different but I'm not an expert...

If Tesla want's to continue to stick it to the oil companies they will not use plastic body panels, including carbon fiber. I think they have substantial know how with aluminum and will continue the path. There are many articles that say Model 3 will be made of steel and I just don't see it. I thought that perhaps Tesla paintshop could give us a hint.

If Tesla want's to continue to stick it to the oil companies they will not use plastic body panels, including carbon fiber. I think they have substantial know how with aluminum and will continue the path. There are many articles that say Model 3 will be made of steel and I just don't see it. I thought that perhaps Tesla paintshop could give us a hint.

Shocker: model s has some steel body parts.

At most there will be more of them in model E where weight differential is overweigthed by price differential.

At most there will be more of them in model E where weight differential is overweigthed by price differential.

There are many articles out there on how the Model 3 will make much more use of steel.

Here's one: http://www.teslarati.com/tuned-third-generation-tesla-model-e-will-utilize-steel-construction/

Here's one: http://www.teslarati.com/tuned-third-generation-tesla-model-e-will-utilize-steel-construction/

FlatSix911

Porsche 918 Hybrid

A4 is aluminum intensive, but still far less aluminum than the Model S for example. Most of it is steel, esp. the chassis:

http://www.repairerdrivennews.com/2...-264-6-pounds-lighter-includes-more-aluminum/

I suspect the Model 3 will be similar.

Questions we're not really able to answer, but which Tesla likely is figuring out right now: How much of the cost of an Audi A4 (comparable aluminum-intensive benchmark for the Model 3 starting at $35,900) made up of the drivetrain vs. the aluminum-intensive body? How much battery capacity is saved to hit target range by using aluminum, and is that cheaper than using (and tooling up for) steel? Does going with aluminum for the 3 help them get better pricing for aluminum on the battery packs, S and X - increasing margins there?

Not much Aluminum on the new Audi A4 ... only the red and blue areas highlighted below.

Audi USA vaguely described the eighth-generation 2013 Audi A4 as a “galvanized steel unibody construction with aluminum hood”

MassModel3

Member

I've wondered that, too. The new aluminum is something like 40% lighter, easier to stamp, and stronger. What I don't know is where it is cost versus today's aluminum.I wonder if Tesla are talking to, or at least considering, Alcoa in regards to their new alloy tech they announced around a year ago. I think Ford are looking to use them very soon.

dgpcolorado

high altitude member

My impression is that the weight saving advantages of aluminum wrt battery size aren't all that large. At highway speeds drag is the main limit on range. In stop-and-go traffic weight is an issue for acceleration energy but some of that is (usually) recovered by regen braking, unlike in an ICE car. And stop and go traffic tends to be at lower speeds, meaning lower drag. I don't buy the idea that aluminum will have a significant impact on the battery size needed for a given range.

One advantage of reducing the weight in the Model S with aluminum is improving drag race type acceleration and performance. With the Model 3 cost savings should be more important than 0-60 times.

One advantage of reducing the weight in the Model S with aluminum is improving drag race type acceleration and performance. With the Model 3 cost savings should be more important than 0-60 times.

Similar threads

- Article

- Replies

- 0

- Views

- 1K

- Replies

- 15

- Views

- 828

- Replies

- 4

- Views

- 259