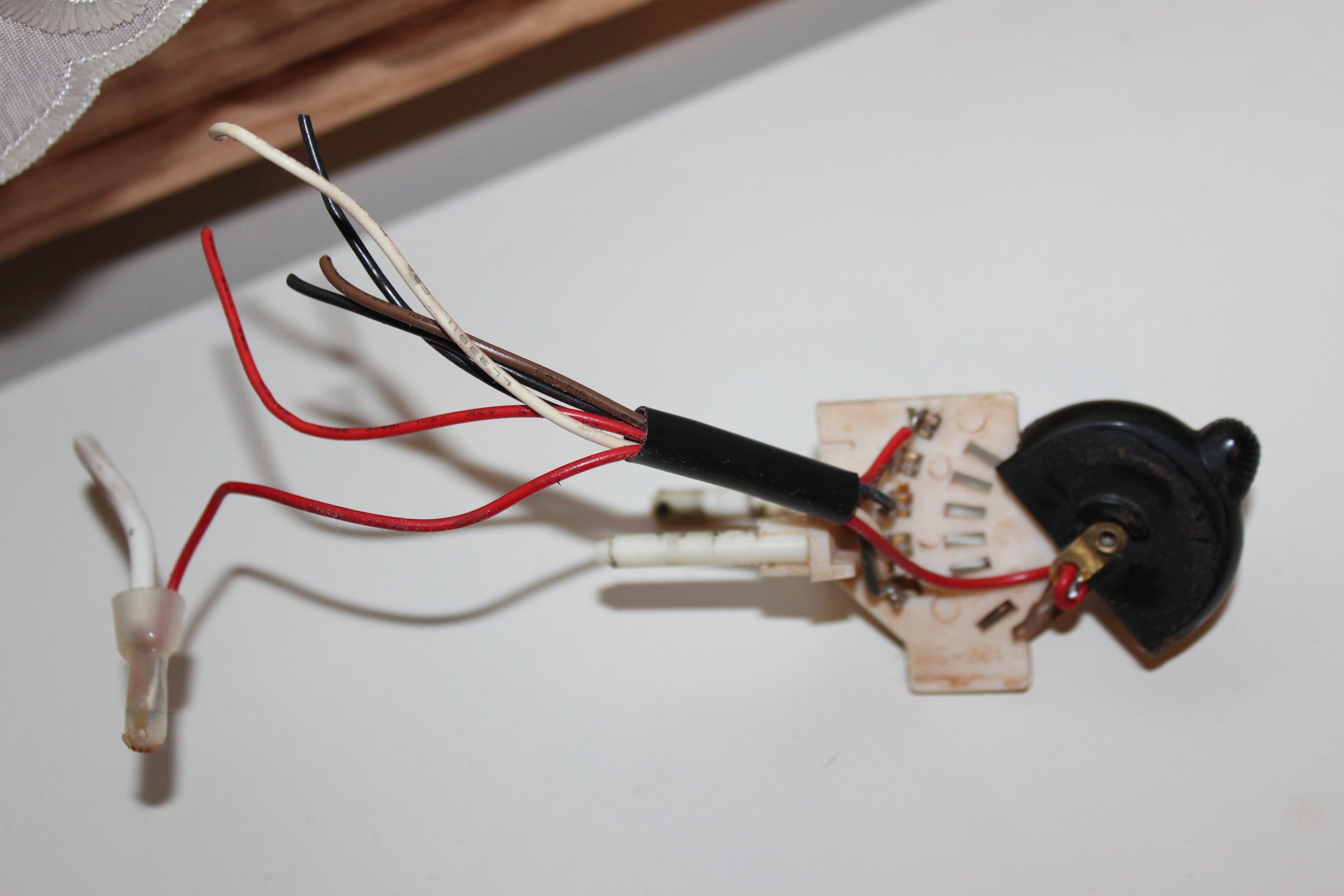

Hey guys, got a question I'm hoping you can answer. So brief story about why this came up. My mom's electric hand mixer made a weird noise and had plastic something rattling inside. She decided to get she'll get another one since this one was like 25 years old so I decided to take it apart. After doing that is when my question came to me. In picture one here:

You can see all the wires. The black control is what allows you to change the speed. The red wire going to that black control (which also has the cap on it on the other end) came from the plug (along with the white wire coming from the cap which went to the electric motor). The other wires are attched to the metal connectors better seen in picture two here:

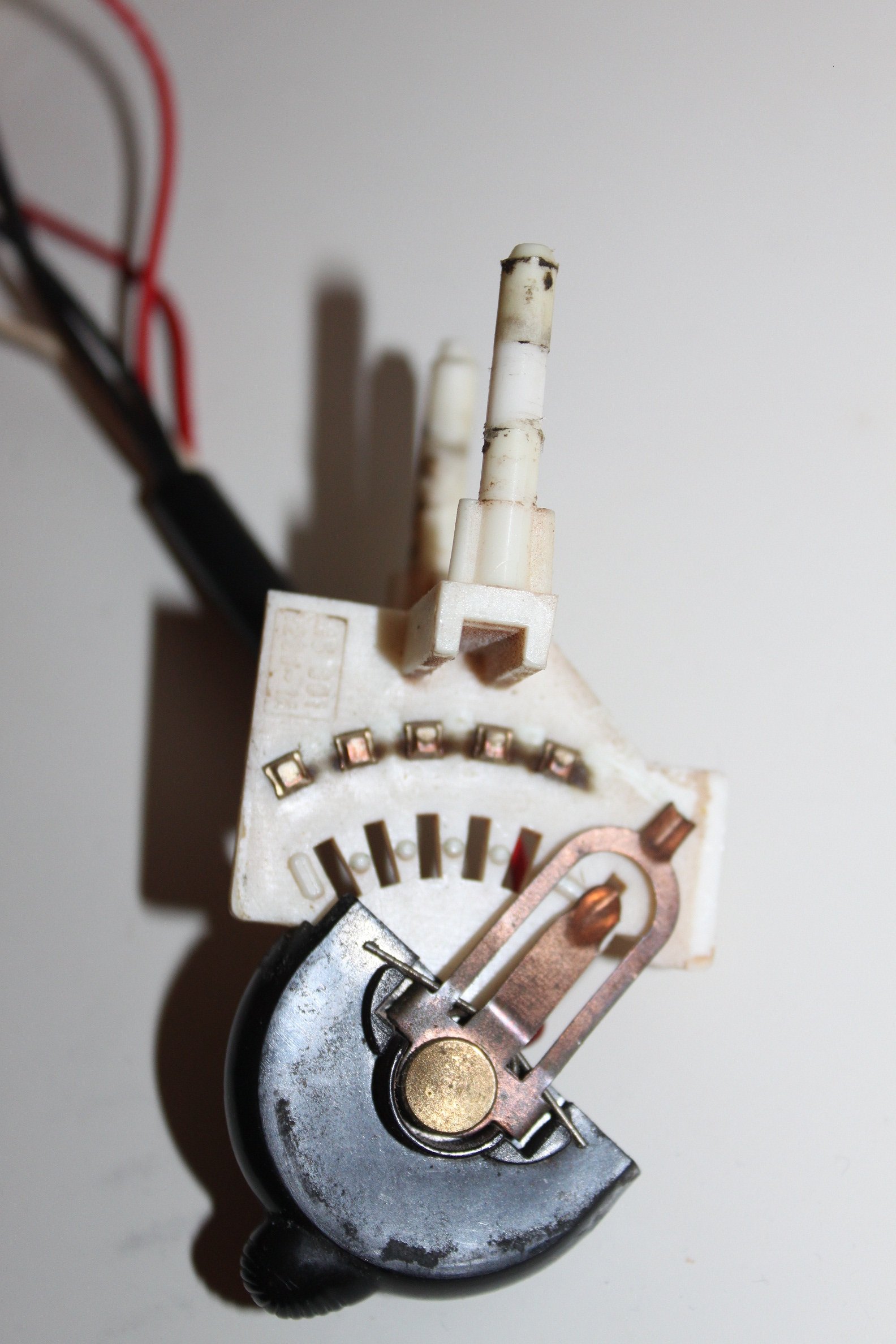

Now I know that the electricity comes from the red wire to the black controller. I also know that when the black controller gets moved to the 5 different speeds it has, the metal piece makes contact with the metal piece in the plastic to complete the circuit thus making the motor engage. My question is this. How exactly is the variable speed controlled. The problem I am having understanding in my mind is that only so much electricity would be coming in through the plug. With that I thought of a few ways it could work but one didn't really make sense to me. First thing I thought of was this (and I'm going to use terminology possibly incorrectly so please bare with me and feel free to let me know the proper terms. I was using currents where volts was but changed that, still not sure if it's correct but sounds better). So (just to have a number, I was talking with my dad about this) I said say there is 10 volts of electricity coming into the mixer. If 10 currents is the max that can come through the plug than maybe each contact get 10 currents (after my dad said they are probably connected). After saying that though I had a problem with each contact getting 10 volts if 10 volts was the max the plug could handle.

So after a little more talking with my dad I suggested maybe the current gets split up. So by that I mean when the contact hits the first speed it is getting 2 volts, when it hits the second contact that one also gets 2 for a total of 4 volts making the motor spin faster. This would allow 10 volts total when the last and fastest speed is on because the 5th contact is being contacted. The only problem I had with this is my dad said a resistor would be used to accomplish (he has a minimum knowledge of electrical work and is not comfortable with doing more than basic wiring, so if there is more to it than he wouldn't know). So if a resistor is needed, I don't see where it would have been because I figure it would need to be before the contact?

So, if you didn't want to read all that, my question is basically, how does the variable speed actually work to get the different power requirements to change the speed of the motor?

Appreciate the time taken to read and/or respond to this. I know there are smart people on this board and I couldn't find the answer with what I was searching on google.

-Shark2k

You can see all the wires. The black control is what allows you to change the speed. The red wire going to that black control (which also has the cap on it on the other end) came from the plug (along with the white wire coming from the cap which went to the electric motor). The other wires are attched to the metal connectors better seen in picture two here:

Now I know that the electricity comes from the red wire to the black controller. I also know that when the black controller gets moved to the 5 different speeds it has, the metal piece makes contact with the metal piece in the plastic to complete the circuit thus making the motor engage. My question is this. How exactly is the variable speed controlled. The problem I am having understanding in my mind is that only so much electricity would be coming in through the plug. With that I thought of a few ways it could work but one didn't really make sense to me. First thing I thought of was this (and I'm going to use terminology possibly incorrectly so please bare with me and feel free to let me know the proper terms. I was using currents where volts was but changed that, still not sure if it's correct but sounds better). So (just to have a number, I was talking with my dad about this) I said say there is 10 volts of electricity coming into the mixer. If 10 currents is the max that can come through the plug than maybe each contact get 10 currents (after my dad said they are probably connected). After saying that though I had a problem with each contact getting 10 volts if 10 volts was the max the plug could handle.

So after a little more talking with my dad I suggested maybe the current gets split up. So by that I mean when the contact hits the first speed it is getting 2 volts, when it hits the second contact that one also gets 2 for a total of 4 volts making the motor spin faster. This would allow 10 volts total when the last and fastest speed is on because the 5th contact is being contacted. The only problem I had with this is my dad said a resistor would be used to accomplish (he has a minimum knowledge of electrical work and is not comfortable with doing more than basic wiring, so if there is more to it than he wouldn't know). So if a resistor is needed, I don't see where it would have been because I figure it would need to be before the contact?

So, if you didn't want to read all that, my question is basically, how does the variable speed actually work to get the different power requirements to change the speed of the motor?

Appreciate the time taken to read and/or respond to this. I know there are smart people on this board and I couldn't find the answer with what I was searching on google.

-Shark2k