mod note: This conversation moved out of CHAdeMO adapter thread in Model S forum

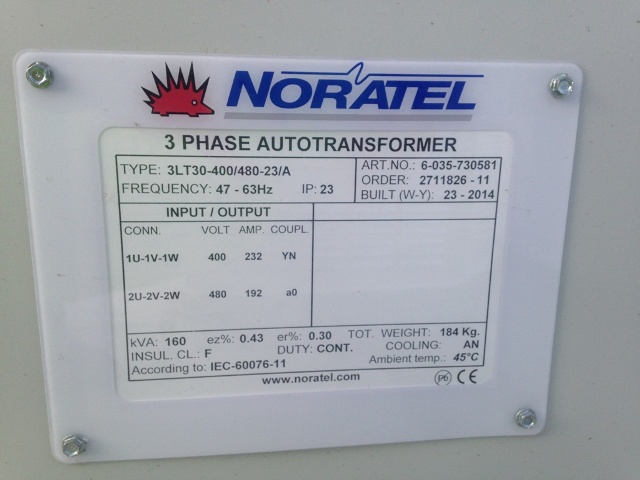

Nevertheless, all newer Norwegian SC sites have the step-up transformers. Here is a picture of the label:

480V 3-phase 192A is 160kW, same as the transformer rating, and the neccessary input power to achieve 150kW output (since chargers are not 100% efficient).

If you still don't believe me about the transformers I'll take an overview picture of Solli SC. I also have the building permits which goes into details about the transformers, but they are in Norwegian.

As for the internal SC configuration, my guess is 15x10kW US units. 480V is what they use in the US so it makes sense to do the same here.

The 330A limit is for one connector, not the total power shared. Yes, I am sure we shared. I checked the labeling, we were the only two cars there and the other car was nowhere near full battery. 120kW for me and 30kW for him. If he was on another SC he would get way more than 30kW. Also there was a tech on site working on the SCs, he said he was upgrading them. I do not know what he was upgrading, but he confirmed 150kW per cabinet rating.

My guess is the newer US Superchargers also have 15 10kW units, while the old ones had 12 units. Instead of continuing with two lines they are probably standarising on the US configuration.

Sorry but that bears no resemblance to what I have seen in the UK, and goes against all the arguments/logic about how SC cabinets are configured in the US and elsewhere that I have seen. Do you have a source/reference for this? Examples of such transformers in use? Which country have you seen this setup in?

US SC units are a stack of twelve x 10kW charge units (same as the ones in US cars) hence 120kW.

EU SC units are a stack of twelve x 11kW 3 phase charge units (same as the ones in EU cars) hence 132kW which is rounded up to 135kW for labeling.

There are no step up transformers at any UK supercharger site that I've visited or seen photos of.

In countries where 400V 3 phase power is common why on earth would you go to the huge expense and hassle of stepping up slightly to 480V?

The rating label on a Gen II 135kW supercharger says input of 380-480V 3phase at up to 192A. 192A is exactly what you need to drive 12 European charge modules at 16A per phase each. That's 133kW total at an EU standard 400V (230V L-N on each phase).

Nevertheless, all newer Norwegian SC sites have the step-up transformers. Here is a picture of the label:

480V 3-phase 192A is 160kW, same as the transformer rating, and the neccessary input power to achieve 150kW output (since chargers are not 100% efficient).

If you still don't believe me about the transformers I'll take an overview picture of Solli SC. I also have the building permits which goes into details about the transformers, but they are in Norwegian.

As for the internal SC configuration, my guess is 15x10kW US units. 480V is what they use in the US so it makes sense to do the same here.

The maximum current output of a Gen II 135kW supercharger is 330A continuous so it could not possibly charge two cars at a total of 150kW between them. When you and an adjacent car saw a total that exceeded 120kW are you sure that you were both connected to the same SC cabinet. At some large SC sites the paired bays aren't adjacent - they sometimes install them as e.g. 1A 2A 3A 4A 1B 2B 3B 4B.

The 330A limit is for one connector, not the total power shared. Yes, I am sure we shared. I checked the labeling, we were the only two cars there and the other car was nowhere near full battery. 120kW for me and 30kW for him. If he was on another SC he would get way more than 30kW. Also there was a tech on site working on the SCs, he said he was upgrading them. I do not know what he was upgrading, but he confirmed 150kW per cabinet rating.

My guess is the newer US Superchargers also have 15 10kW units, while the old ones had 12 units. Instead of continuing with two lines they are probably standarising on the US configuration.

Last edited by a moderator: