I have decided to post this in the investor section not in the future cars section because I believe it could be much more significant from an investors’ perspective.

A few important considerations:

Gigafactory

Consider that after 2018 Tesla will have a Gigafactory up and running with a viable reduced cost of the batteries and potentially increased energy density and enormous battery output.

The superchargers

The second important assumption in my reasoning is that Tesla is continuing to expand the Supercharging stations worldwide and by 2020 they will become totally able to support large fleets. Also consider the nature of these segments where the heavy trucks are not allowed to enter most parts of the cities and are transporting goods mainly via highways and motorways exactly where Tesla superchargers are located. Additionally the drivers are obligated via regulations to take breaks and they have limits of their driving time which is also suitable for supercharging.

Market summary

Industry revenue is $242bn from 30 million vehicles annually

Tesla advantages

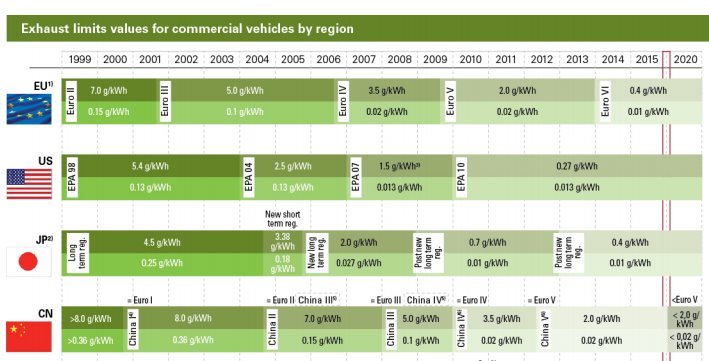

-Environmental regulations- OEMs are faced with constantly increasing environment standards and regulations.

Pressure on total cost of ownership

Fuel costs dominate the total cost of ownership in mature markets.

The commercial vehicle business has always been characterized by an emphasis on

total cost of ownership (TCO). As an investment asset, the acquisition and operating

costs of a commercial vehicle naturally have a direct influence on the profit margins

of truck operators. The typical TCO in a mature commercial vehicle market differs

substantially from an emerging market. In the emerging markets of Asia in particular,

the acquisition price still plays a dominant role in the TCO over the lifetime of a truck.

Over the medium to long term, however, it is likely that the TCO model in emerging

markets will develop along similar lines to mature markets, particularly with regard to

rising fuel costs, as well as growing demand for service and repair.

The reduction of the TCO by commercial vehicle manufacturers is crucial since it is

virtually impossible for haulers to pass a rising TCO on to freight prices due to the

intense competitive pressure. The largest TCO component that can be influenced in

mature markets such as Western Europe is fuel costs (30 percent from the overall TCO).

However, the reduction of TCO from the manufacturer’s side is not easy, as the most

influential components of TCO are to do with the regulatory environment (ecological

requirements, taxes and tolls), particularly in mature markets and increasingly in

emerging markets as well. It is likely that these external factors will continue to grow

in importance, weakening the ability of manufacturers to influence the TCO for the

benefit of their customers.

Customers’ perspective

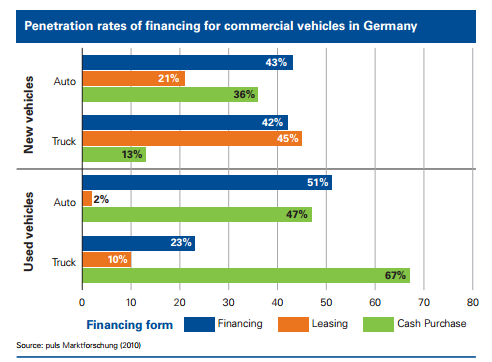

Customers are typically all-size businesses. From my professional contacts I can say that the profit margins in logistics are usually low in the range of 10-12% . The common practice in the field is purchasing new trucks using leasing and different financial services so it does not require a big upfront investment to replace old trucks with increasing depreciation costs and high fuel consumption. Old trucks are typically sold to smaller companies which provides operational cash for the company.

Replacing old fleet is an occasional process for businesses. It makes economic sense and it is naturally needed every 4-5 years.

Disruptive Tesla effect

Let’s assume that Tesla enters the HCV market with an Electric Heavy Commercial Vehicle on average market prices, combined with a Supercharging infrastructure where charging is not free but 50% cheaper than fuel costs (for example), fulfilling all of the environmental requirements at once.

For the particular example of a European company with 30% fuel costs and profit margins of 12% this cost reduction will translate in doubling profit margins to 25-27%. This could be a dramatic improvement with almost no upfront cost using standard market practices of replacing old vehicles. Long term effect could be even more significant because inevitably some companies will translate partially the savings to the end price so it will provide a price advantage for their customers. Once this process starts to accelerate all other companies will have to shift to electric HCV otherwise they will not be competitive. I am excluding possible incentives and maintenance cost reductions which are highly possible.

The Business case for Tesla

If this business case is executed by Tesla Motors it will provide 3 main streams of revenue:

•Entering a new vehicle segment

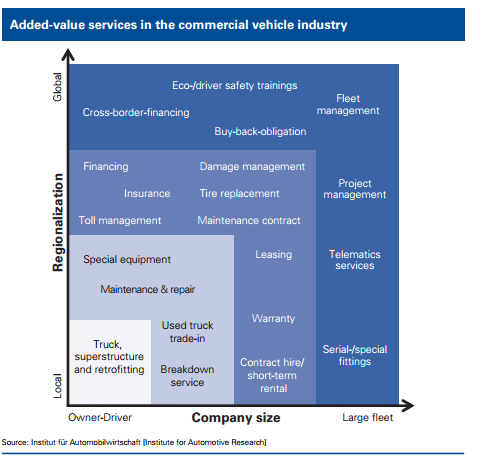

•After sale market: maintenance, fleet management systems, telematics totally required from each HCV owner

•Reselling the electricity from utilities trough superchargers to end customers which represents a constant revenue stream from each unit sold as long as it is operational.

Typically each HCV in logistics travels from 7000 miles to 20 000 miles per month (depending on the number of drivers). Anyway, I strongly believe that this case will be particularly successful in Europe where fuel prices are really high (EU average $7,60 per gallon where up to 50% are taxes) and electricity is relatively cheap $0,2 per KW/h.

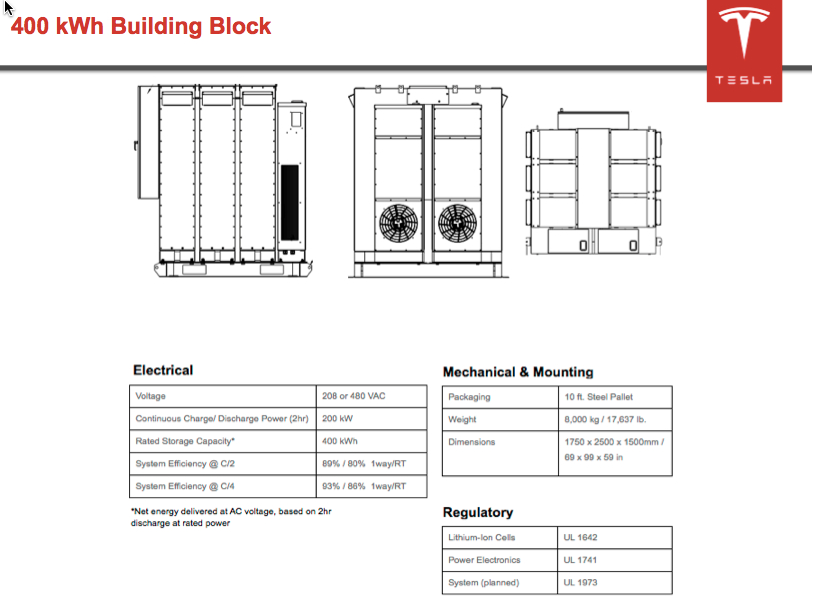

An interesting reference here are the stationary storage packs. JB Straubel said that 5 packs with a total of 2 megawatt-hour are managing 10 percent of peak demand in the Fremont Tesla factory.

I am making a totally speculative calculation. This may be too far from the optimal numbers but to have some starting point of my illustrational calculation I will assume that Tesla could use one 400KW battery pack in their Electric HCV with a maximum range of 1000 km (621 miles) - I believe this is a conservative number considering the technological improvement in energy density and scaled battery packs. With $0,2 per KWh the price in Europe for 1000km with potential Tesla E-HCV will be $80.

To compare: the last Mercedes Actros from 2014 (one of the most efficient HCV’s on the market) has a consumption of 25,9 liters per 100 km (I believe 9 miles per gallon), according to Mercedes in perfect conditions. This consumption translates into a cost of approximately $500 per 1000 km in Europe (621 miles) with an average monthly mileage of 10 000 km (again a strongly conservative number) which translates into a $5 000 monthly cost -> $55 000 annual fuel costs, because each vehicle is only on the road for 11 out of 12 months (the remaining month is used for maintenance and inspections).

If we follow the previous case with a 50% cost reduction for Electric HCV’s in European logistic companies (which in my opinion is a totally sufficient advantage for companies to switch to electricity) in this projection Tesla can charge $250 per 400KW of supercharging or even less. Assuming again 10 000 km per month per E-HCV, Tesla will get an annual average revenue of $27 500 only from supercharging each E-HCV sold.

I will be happy to see other calculations from different geographical regions.

My conclusion is that if Tesla keeps on its vision for transition to sustainable transportation they will have to produce E-HCV’s not because they could realize greater profits but because the current industry is among the main reasons for pollution.

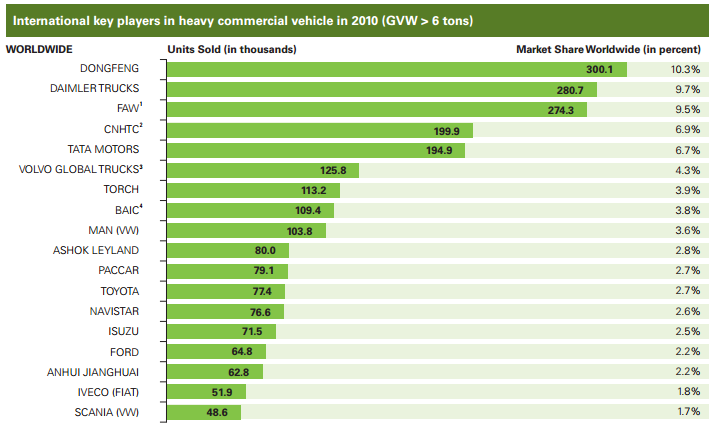

Tesla may also have a different approach, such as signing deal with Mercedes for example, since they are currently partners. After all, MB have 280 000 annual HCV sales.

My professional interest and experience is based on fleet management solutions for logistic companies.

A few important considerations:

Gigafactory

Consider that after 2018 Tesla will have a Gigafactory up and running with a viable reduced cost of the batteries and potentially increased energy density and enormous battery output.

The superchargers

The second important assumption in my reasoning is that Tesla is continuing to expand the Supercharging stations worldwide and by 2020 they will become totally able to support large fleets. Also consider the nature of these segments where the heavy trucks are not allowed to enter most parts of the cities and are transporting goods mainly via highways and motorways exactly where Tesla superchargers are located. Additionally the drivers are obligated via regulations to take breaks and they have limits of their driving time which is also suitable for supercharging.

Market summary

Industry revenue is $242bn from 30 million vehicles annually

Tesla advantages

-Environmental regulations- OEMs are faced with constantly increasing environment standards and regulations.

Pressure on total cost of ownership

Fuel costs dominate the total cost of ownership in mature markets.

The commercial vehicle business has always been characterized by an emphasis on

total cost of ownership (TCO). As an investment asset, the acquisition and operating

costs of a commercial vehicle naturally have a direct influence on the profit margins

of truck operators. The typical TCO in a mature commercial vehicle market differs

substantially from an emerging market. In the emerging markets of Asia in particular,

the acquisition price still plays a dominant role in the TCO over the lifetime of a truck.

Over the medium to long term, however, it is likely that the TCO model in emerging

markets will develop along similar lines to mature markets, particularly with regard to

rising fuel costs, as well as growing demand for service and repair.

The reduction of the TCO by commercial vehicle manufacturers is crucial since it is

virtually impossible for haulers to pass a rising TCO on to freight prices due to the

intense competitive pressure. The largest TCO component that can be influenced in

mature markets such as Western Europe is fuel costs (30 percent from the overall TCO).

However, the reduction of TCO from the manufacturer’s side is not easy, as the most

influential components of TCO are to do with the regulatory environment (ecological

requirements, taxes and tolls), particularly in mature markets and increasingly in

emerging markets as well. It is likely that these external factors will continue to grow

in importance, weakening the ability of manufacturers to influence the TCO for the

benefit of their customers.

Customers’ perspective

Customers are typically all-size businesses. From my professional contacts I can say that the profit margins in logistics are usually low in the range of 10-12% . The common practice in the field is purchasing new trucks using leasing and different financial services so it does not require a big upfront investment to replace old trucks with increasing depreciation costs and high fuel consumption. Old trucks are typically sold to smaller companies which provides operational cash for the company.

Replacing old fleet is an occasional process for businesses. It makes economic sense and it is naturally needed every 4-5 years.

Disruptive Tesla effect

Let’s assume that Tesla enters the HCV market with an Electric Heavy Commercial Vehicle on average market prices, combined with a Supercharging infrastructure where charging is not free but 50% cheaper than fuel costs (for example), fulfilling all of the environmental requirements at once.

For the particular example of a European company with 30% fuel costs and profit margins of 12% this cost reduction will translate in doubling profit margins to 25-27%. This could be a dramatic improvement with almost no upfront cost using standard market practices of replacing old vehicles. Long term effect could be even more significant because inevitably some companies will translate partially the savings to the end price so it will provide a price advantage for their customers. Once this process starts to accelerate all other companies will have to shift to electric HCV otherwise they will not be competitive. I am excluding possible incentives and maintenance cost reductions which are highly possible.

The Business case for Tesla

If this business case is executed by Tesla Motors it will provide 3 main streams of revenue:

•Entering a new vehicle segment

•After sale market: maintenance, fleet management systems, telematics totally required from each HCV owner

•Reselling the electricity from utilities trough superchargers to end customers which represents a constant revenue stream from each unit sold as long as it is operational.

Typically each HCV in logistics travels from 7000 miles to 20 000 miles per month (depending on the number of drivers). Anyway, I strongly believe that this case will be particularly successful in Europe where fuel prices are really high (EU average $7,60 per gallon where up to 50% are taxes) and electricity is relatively cheap $0,2 per KW/h.

An interesting reference here are the stationary storage packs. JB Straubel said that 5 packs with a total of 2 megawatt-hour are managing 10 percent of peak demand in the Fremont Tesla factory.

I am making a totally speculative calculation. This may be too far from the optimal numbers but to have some starting point of my illustrational calculation I will assume that Tesla could use one 400KW battery pack in their Electric HCV with a maximum range of 1000 km (621 miles) - I believe this is a conservative number considering the technological improvement in energy density and scaled battery packs. With $0,2 per KWh the price in Europe for 1000km with potential Tesla E-HCV will be $80.

To compare: the last Mercedes Actros from 2014 (one of the most efficient HCV’s on the market) has a consumption of 25,9 liters per 100 km (I believe 9 miles per gallon), according to Mercedes in perfect conditions. This consumption translates into a cost of approximately $500 per 1000 km in Europe (621 miles) with an average monthly mileage of 10 000 km (again a strongly conservative number) which translates into a $5 000 monthly cost -> $55 000 annual fuel costs, because each vehicle is only on the road for 11 out of 12 months (the remaining month is used for maintenance and inspections).

If we follow the previous case with a 50% cost reduction for Electric HCV’s in European logistic companies (which in my opinion is a totally sufficient advantage for companies to switch to electricity) in this projection Tesla can charge $250 per 400KW of supercharging or even less. Assuming again 10 000 km per month per E-HCV, Tesla will get an annual average revenue of $27 500 only from supercharging each E-HCV sold.

I will be happy to see other calculations from different geographical regions.

My conclusion is that if Tesla keeps on its vision for transition to sustainable transportation they will have to produce E-HCV’s not because they could realize greater profits but because the current industry is among the main reasons for pollution.

Tesla may also have a different approach, such as signing deal with Mercedes for example, since they are currently partners. After all, MB have 280 000 annual HCV sales.

My professional interest and experience is based on fleet management solutions for logistic companies.