So, I self installed my HPWC not long ago, but before I had my second onboard charger so hadn't been able to run it at 80A until recently.

I used 2 gauge copper for about a 35ft run (8 gauge for ground). 100 amp circuit for 80 amp charging. Used 3/4" steel conduit for the exposed portions and 3/4" plastic flex (90C rated) for the hidden portions.

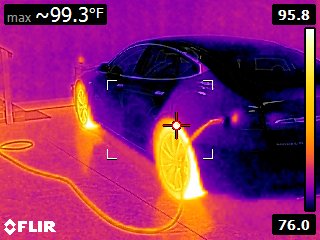

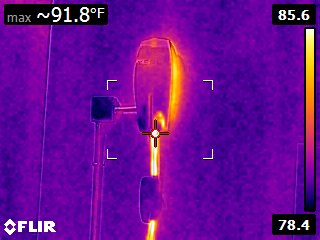

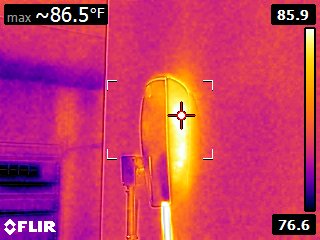

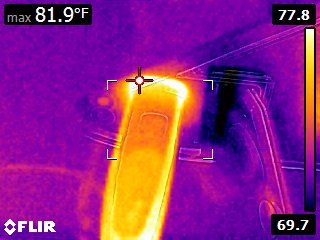

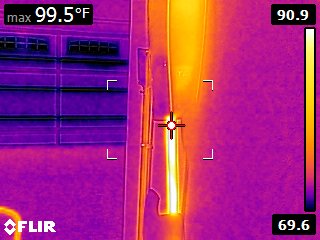

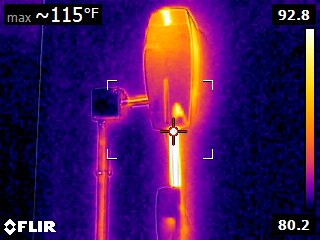

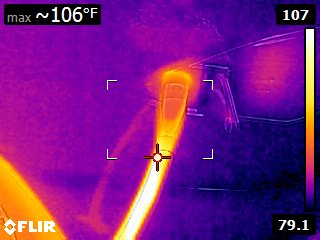

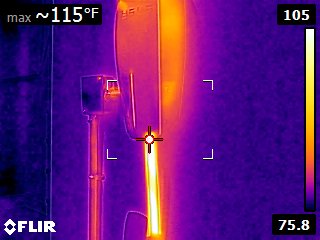

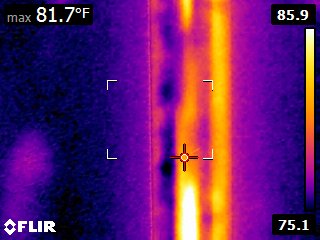

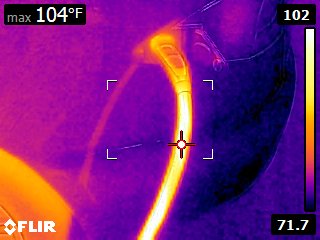

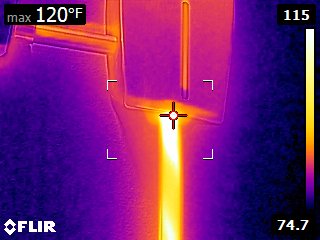

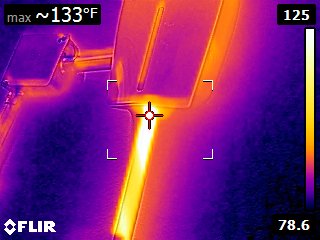

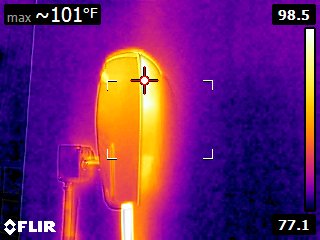

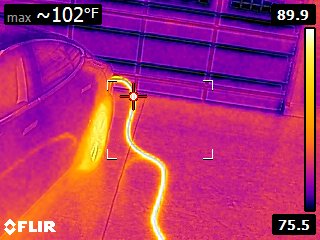

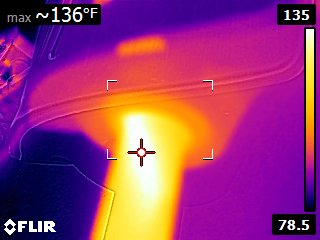

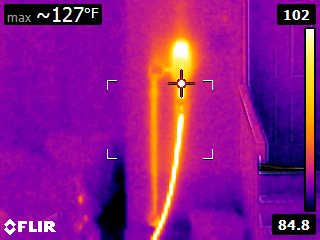

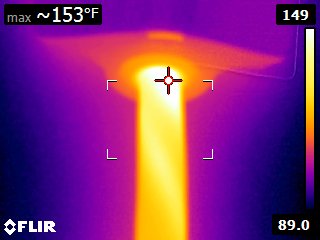

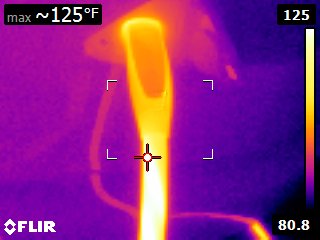

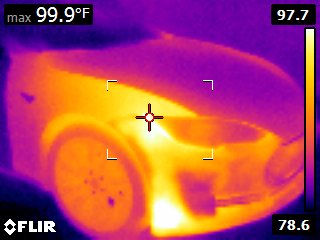

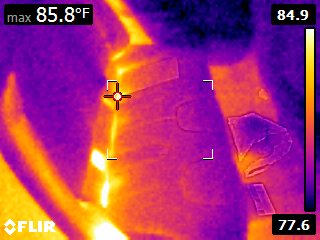

Since I heard some reports around the interwebs that the HPWC gets very hot, I hung around with the FLIR cam the first time using it at a full 80A to see how things went. Here are the results of more fun with the FLIR cam:

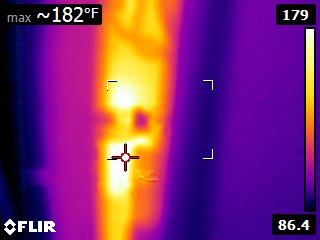

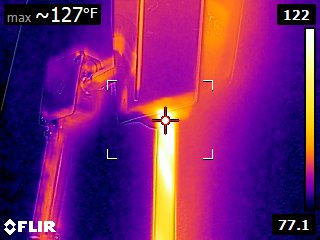

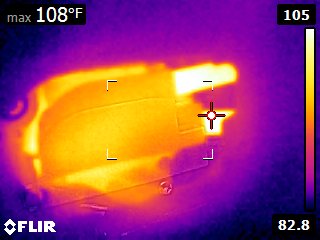

The one pic that shows 182F is where I pulled the top of the HPWC cover off and peeked inside... I was beat from my ~570 mile drive, and, I was satisfied that with these readings that something bad was unlikely, and called it a day (was about 5AM...)

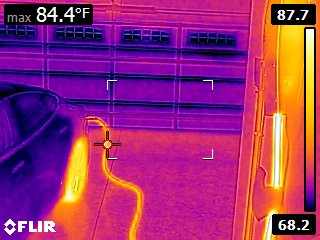

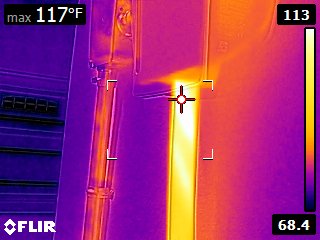

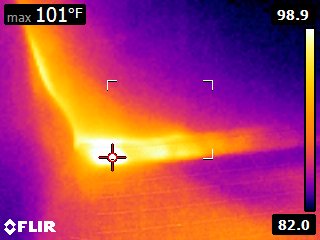

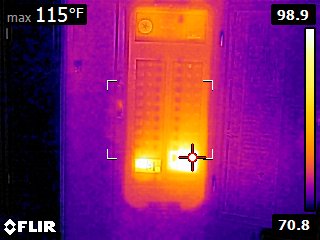

The next day I installed a TED Pro energy monitoring device on both of my panels, along with some whole panel surge suppressors... then I took a trip about 100 miles east, then back. Returned pretty late and started to recharge. After about 90 minutes I took some more pics...

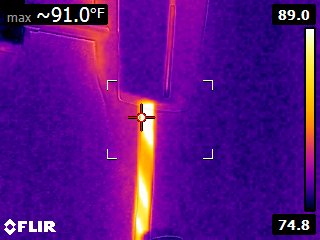

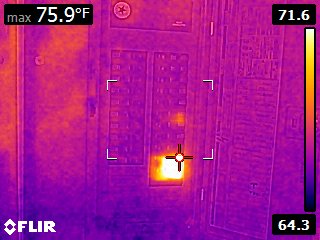

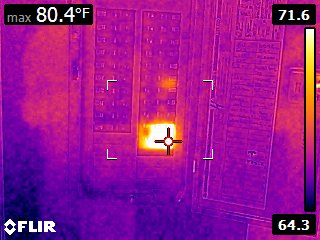

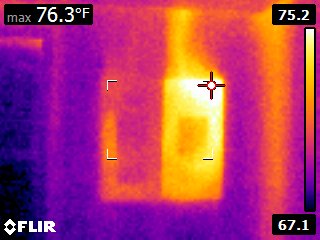

The one of the two panels looks alarming at first, until you realize that the highest temp in that pic is 76F. Cam is just sensitive, which is awesome.

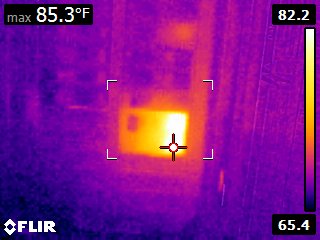

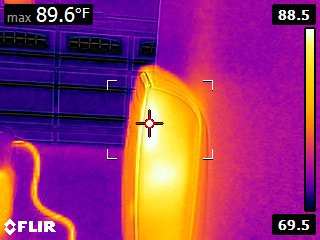

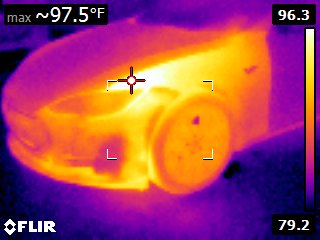

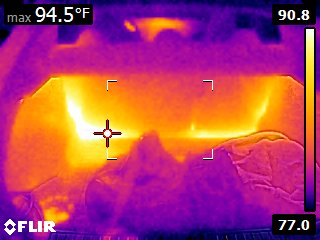

I thought it was interesting that heat from the two internal chargers sneaked through to the interior a little too.

Here are the two PDFs from the FLIR software also (they have the real-color images that go with the above):

HPWC @ 80A.pdf

HPWC @ 80A after 90 minutes.pdf

It seems to do fine for the ~4 hours needed for a full charge. It does get pretty hot, but not dangerously hot. The wiring and conduit I used is rated to 90C (194F) and the wiring Tesla used for the HPWC is rated to 105C (221F). I didn't see any temps get near these. The exception being inside the HPWC where the components do seem to get very hot (182F noted). The cable as it exits the HPWC gets hot, but cools within a few feet of it. I'll investigate all of this further next time I have the time.

See also my Supercharger IR pics thread

I used 2 gauge copper for about a 35ft run (8 gauge for ground). 100 amp circuit for 80 amp charging. Used 3/4" steel conduit for the exposed portions and 3/4" plastic flex (90C rated) for the hidden portions.

Since I heard some reports around the interwebs that the HPWC gets very hot, I hung around with the FLIR cam the first time using it at a full 80A to see how things went. Here are the results of more fun with the FLIR cam:

The one pic that shows 182F is where I pulled the top of the HPWC cover off and peeked inside... I was beat from my ~570 mile drive, and, I was satisfied that with these readings that something bad was unlikely, and called it a day (was about 5AM...)

The next day I installed a TED Pro energy monitoring device on both of my panels, along with some whole panel surge suppressors... then I took a trip about 100 miles east, then back. Returned pretty late and started to recharge. After about 90 minutes I took some more pics...

The one of the two panels looks alarming at first, until you realize that the highest temp in that pic is 76F. Cam is just sensitive, which is awesome.

I thought it was interesting that heat from the two internal chargers sneaked through to the interior a little too.

Here are the two PDFs from the FLIR software also (they have the real-color images that go with the above):

HPWC @ 80A.pdf

HPWC @ 80A after 90 minutes.pdf

It seems to do fine for the ~4 hours needed for a full charge. It does get pretty hot, but not dangerously hot. The wiring and conduit I used is rated to 90C (194F) and the wiring Tesla used for the HPWC is rated to 105C (221F). I didn't see any temps get near these. The exception being inside the HPWC where the components do seem to get very hot (182F noted). The cable as it exits the HPWC gets hot, but cools within a few feet of it. I'll investigate all of this further next time I have the time.

See also my Supercharger IR pics thread

Last edited: