So i lowered my car using the factory sensors and factory links. i only went about 3/4 - 1 inch all around. when i originally ordered the car, i assumed buying and installing springs would run around 900-1400 aftermarket (if it was even available, my ls460 too almost a year after they released the car before aftermarket springs were available) and its non adjustable without taking off the rims and adjusting the coil overs.

At a $1500 option the adjustable air ride was a no brainer. even set at low with the factory setup, it still wasn't as low as i wanted to go (esp with 22's installed) , but with the in dash adjustable air ride, this is the perfect set up cause i can park it low and dive it high.

I just wished they had a setting to set it automatically at speeds that was user adjustable. Ie.. parked, slam to ground like a range rover ( how sick is it when your car kneels for you when you walk up!!!) and raise back up to a preset height when your driving at a certain speed. maybe in tesla model S v2.0 huh.. lol

I do realize that there are going to be some people that are going to say leave it stock, your going to mess up the alignment, your not suppose to do that, blah blah blah, you know where this is going so please save it for another thread. this is my car, this is how i like it, if your interested in doing the same and save some time and money, keep reading, if not, no one is holding a gun to your head to force you to do what im doing or forcing you to keep reading right?

oh yeah, this took me a whole hour and half to get done so not much work at all if you have the right tools. if i needed to do it again, knowing what i know now, probably would take me about an hour max.

here we go. step 1: Jack up the car on one side using the jack points (remember to set the suspension to "jack" mode)

I had taken off the front wheels to do an HID install which made it easier but its not absolutely necessary. if you noticed the first sensors i did, i drilled out two holes since i wasn't sure where the first position was going to lower it. i reassembled the tires to the car and had to re-set the position on the first sensor and did all that with the tire on so im sure that it can be done without taking the tires off the car. You do need to jack up the car from the jack points, (don't jack up the car from the suspension) since jacking up the car from the jack points allows the front wheels clearance for you to reach the height sensors.

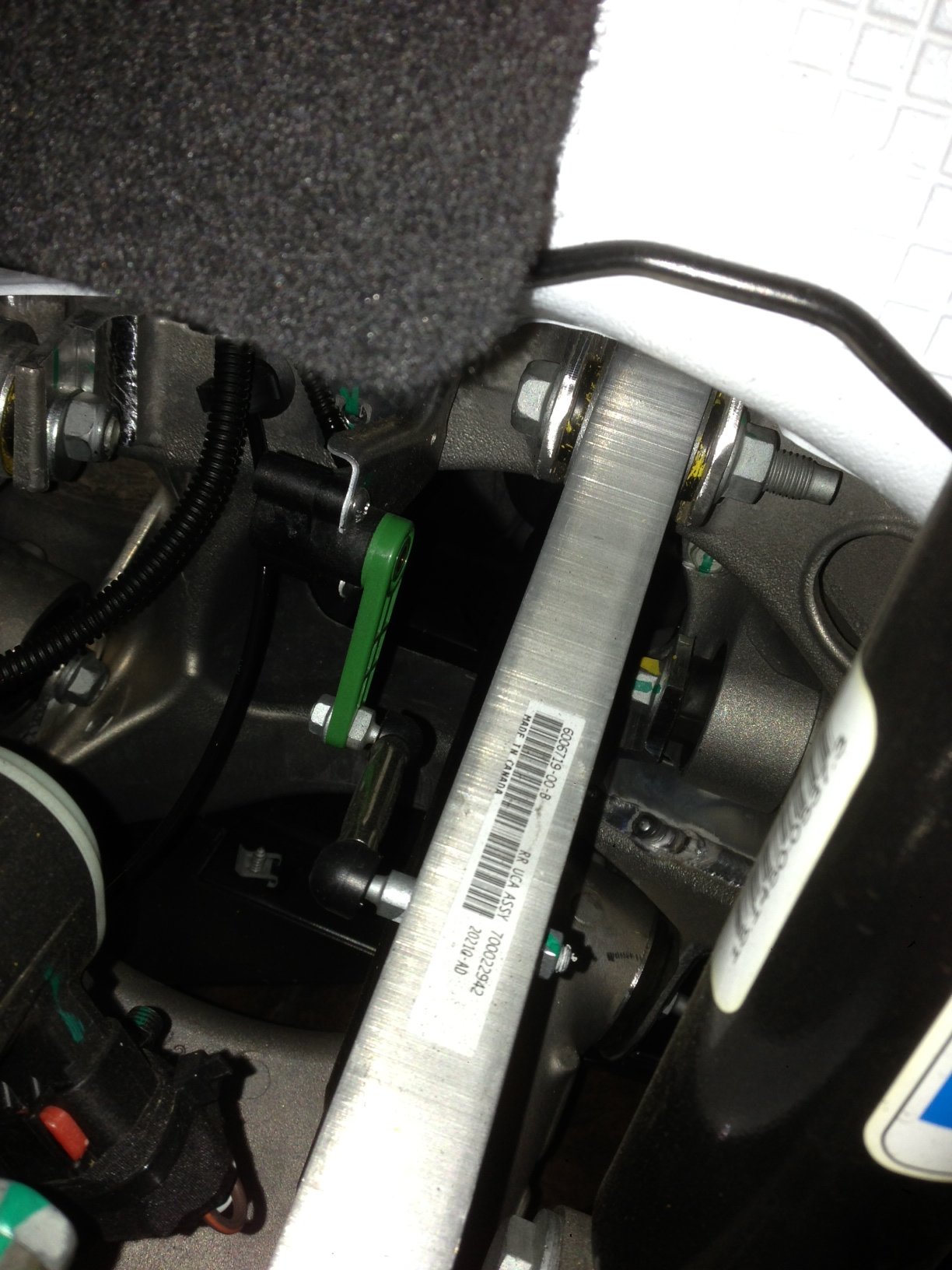

once the wheels are off you see the sensors like these. the first pix are the front sensor, second pix are the rears. make sure you have a 10mm deep socket to take off the nut that hold in the sensor. for some unknown reason, tesla decide to use a bolt that was about 8 times longer than necessary to hold in the sensor. also for another unknown reason, teslamotorclub decides to rotate some of my photo's 90 degrees counter clockwise so if you were laying down sideways in bed while reading, or if you had a real bad kink in your neck to the left, these photos might make sense. lol

Step 2: remove sensors and mark and your drill hole positions.

I found it easiest to stick a screwdriver in the lock notch of the wiring for the sensor and push to get the wiring off. 10mm deep socket to get the nut in front off, bolts in the back off. then hold the linkage in one hand and sensor arm in the other and twist to get the plastic buckle/knuckle thingy off. (yes that a technical term, buckle/knuckle thingy)

Normally, on aftermarket kits that use lowering links, they give you a set of turnbuckles that are adjustable. the longer you make the links, the higher the car thinks it is so in turn it will lower the car to get the sensors to the correct position.

In this case, instead of going out to buy new links to trick the sensor, i reset the mounting points on the sensor side.

I remember my teacher in trigonometry class many many moons ago saying something about fulcrums and angles and what not. some of that applies here to what im doing.....i think....

In laymen's terms, closer the mounting point=longer virtual link=lower car.

If you notice the first picture, i have the first mounting point marked and drilled at exactly 7mm from the CENTER of the oem hole.

Since i didn't know how it affected the height until i reinstalled everything i drilled another hole at 14mm . the reason i chose 7mm is because the oem hole is about 6 mm and that gave me the smallest amount of adjustment while still having some plastic between the holes to keep the structural integrity of the plastic arm.

Turns out that 7mm from the center is about 1/2 in lower. ideally, you want to go 15 mm or exactly where the first cross hash indented in the green sensor arm is to get roughly 1 inch drop. you can probably go to about 1.5 inch drop or roughly 22mm offset from the center of the oem hole. i wouldn't recommend going over 20mm from center though since im not too sure how the angle is affected at the extremes of this setup. (i wasn't the best trigonometry student in my days)

Make sure you mark your drill hole and make a small pilot hole. use about 4-5 steps making your way up to a final hole size of 15/64.

If you go from pilot hole straight to 15/64 like i did on my first try, the plastic bites real quick and you'll be lucky if the whole sensor doest catch and goes flailing around wildly. take your time, its worth it to have a working sensor in the end.

Step 3: reassemble everything and cross your fingers.

For the front sensors, you want to connect the wiring first then the nut then use a channel lock to snap the buckle/knuckle thingy on.

For the rears, you'll want to go buckle/knuckle first, then bolt then wiring.

Thats just how i figured was the easiest route because of the way the wiring and hardware is set up. your results may vary..

The rears link/sensor arm can easily be installed inverted so remember to make a mental or actual pictorial note of how it looks coming out.

Here's a couple before and after pix of the car:

Front and rear 3/4 view. stock 19 inch rims. stock height set at standard . lower ugly black plastic trim has been premiered smooth and painted body color.

Pix after i lowered it an inch all around. iphone night camera isn't the best but you get the jist of it. ill take some more pix during the day which shows the front tires tucked in the fenders if set to low setting.

I drive it at standard height setting but i think it looks incredible parked at low setting. at its highest setting, i still have almost same ground clearance as stock so in all honestly, i think i ended up with the best of both worlds.

It looks great and is still absolutly drivable with, I dare say, no noticeable difference from stock in terms of drivability asides being a bit rougher cause i went from 19 inch oem wheels to aftermarket 22 inch wheels.

To top it off, it didn't cost me anything but a couple hours of elbow grease.

At a $1500 option the adjustable air ride was a no brainer. even set at low with the factory setup, it still wasn't as low as i wanted to go (esp with 22's installed) , but with the in dash adjustable air ride, this is the perfect set up cause i can park it low and dive it high.

I just wished they had a setting to set it automatically at speeds that was user adjustable. Ie.. parked, slam to ground like a range rover ( how sick is it when your car kneels for you when you walk up!!!) and raise back up to a preset height when your driving at a certain speed. maybe in tesla model S v2.0 huh.. lol

I do realize that there are going to be some people that are going to say leave it stock, your going to mess up the alignment, your not suppose to do that, blah blah blah, you know where this is going so please save it for another thread. this is my car, this is how i like it, if your interested in doing the same and save some time and money, keep reading, if not, no one is holding a gun to your head to force you to do what im doing or forcing you to keep reading right?

oh yeah, this took me a whole hour and half to get done so not much work at all if you have the right tools. if i needed to do it again, knowing what i know now, probably would take me about an hour max.

here we go. step 1: Jack up the car on one side using the jack points (remember to set the suspension to "jack" mode)

I had taken off the front wheels to do an HID install which made it easier but its not absolutely necessary. if you noticed the first sensors i did, i drilled out two holes since i wasn't sure where the first position was going to lower it. i reassembled the tires to the car and had to re-set the position on the first sensor and did all that with the tire on so im sure that it can be done without taking the tires off the car. You do need to jack up the car from the jack points, (don't jack up the car from the suspension) since jacking up the car from the jack points allows the front wheels clearance for you to reach the height sensors.

once the wheels are off you see the sensors like these. the first pix are the front sensor, second pix are the rears. make sure you have a 10mm deep socket to take off the nut that hold in the sensor. for some unknown reason, tesla decide to use a bolt that was about 8 times longer than necessary to hold in the sensor. also for another unknown reason, teslamotorclub decides to rotate some of my photo's 90 degrees counter clockwise so if you were laying down sideways in bed while reading, or if you had a real bad kink in your neck to the left, these photos might make sense. lol

Step 2: remove sensors and mark and your drill hole positions.

I found it easiest to stick a screwdriver in the lock notch of the wiring for the sensor and push to get the wiring off. 10mm deep socket to get the nut in front off, bolts in the back off. then hold the linkage in one hand and sensor arm in the other and twist to get the plastic buckle/knuckle thingy off. (yes that a technical term, buckle/knuckle thingy)

Normally, on aftermarket kits that use lowering links, they give you a set of turnbuckles that are adjustable. the longer you make the links, the higher the car thinks it is so in turn it will lower the car to get the sensors to the correct position.

In this case, instead of going out to buy new links to trick the sensor, i reset the mounting points on the sensor side.

I remember my teacher in trigonometry class many many moons ago saying something about fulcrums and angles and what not. some of that applies here to what im doing.....i think....

In laymen's terms, closer the mounting point=longer virtual link=lower car.

If you notice the first picture, i have the first mounting point marked and drilled at exactly 7mm from the CENTER of the oem hole.

Since i didn't know how it affected the height until i reinstalled everything i drilled another hole at 14mm . the reason i chose 7mm is because the oem hole is about 6 mm and that gave me the smallest amount of adjustment while still having some plastic between the holes to keep the structural integrity of the plastic arm.

Turns out that 7mm from the center is about 1/2 in lower. ideally, you want to go 15 mm or exactly where the first cross hash indented in the green sensor arm is to get roughly 1 inch drop. you can probably go to about 1.5 inch drop or roughly 22mm offset from the center of the oem hole. i wouldn't recommend going over 20mm from center though since im not too sure how the angle is affected at the extremes of this setup. (i wasn't the best trigonometry student in my days)

Make sure you mark your drill hole and make a small pilot hole. use about 4-5 steps making your way up to a final hole size of 15/64.

If you go from pilot hole straight to 15/64 like i did on my first try, the plastic bites real quick and you'll be lucky if the whole sensor doest catch and goes flailing around wildly. take your time, its worth it to have a working sensor in the end.

Step 3: reassemble everything and cross your fingers.

For the front sensors, you want to connect the wiring first then the nut then use a channel lock to snap the buckle/knuckle thingy on.

For the rears, you'll want to go buckle/knuckle first, then bolt then wiring.

Thats just how i figured was the easiest route because of the way the wiring and hardware is set up. your results may vary..

The rears link/sensor arm can easily be installed inverted so remember to make a mental or actual pictorial note of how it looks coming out.

Here's a couple before and after pix of the car:

Front and rear 3/4 view. stock 19 inch rims. stock height set at standard . lower ugly black plastic trim has been premiered smooth and painted body color.

Pix after i lowered it an inch all around. iphone night camera isn't the best but you get the jist of it. ill take some more pix during the day which shows the front tires tucked in the fenders if set to low setting.

I drive it at standard height setting but i think it looks incredible parked at low setting. at its highest setting, i still have almost same ground clearance as stock so in all honestly, i think i ended up with the best of both worlds.

It looks great and is still absolutly drivable with, I dare say, no noticeable difference from stock in terms of drivability asides being a bit rougher cause i went from 19 inch oem wheels to aftermarket 22 inch wheels.

To top it off, it didn't cost me anything but a couple hours of elbow grease.